How to Cut Your Thumb Off

Warning - down below are some graphic photos. If you are squeamish, click on the BACK button.

Power tools are dangerous. We know that. But with too little experience, or too much experience, accidents happen. This page is intended to remind my readers always to be vigilant.

Semper Vigilante.

Fortunately my thumb is still alive and well. Except for that little chunk of dead flesh on the end. It is dead because it got cut off by the radial arm saw (RAS).

It is a little embarrassing to have an accident like this with a woodworking tool, but that’s how it happened. Wood, as it turns out, is good for making lots of stuff that metal workers need.

(And vice-versa, I would imagine).

All I was doing was cutting a little 4" square of 1/4" plywood.

But let me digress a moment. The RAS and I go back a long way. About 30 years plus or minus a few. Back then I was a young man with a young family living in Vermont.

Didn’t have much money, so I was always looking for a bargain in used tools. The Craftsman 10" RAS was originally owned by a guy who lived alongside a small stream.

The RAS was in an outdoor shed by the stream and had a little rust. Haggled a while over the price, shook hands, loaded it into the Ford F-150 and headed North.

A few quarts of WD-40 took care of the rust, then I set about aligning the saw. If I had known then what I know now, the saw would have been able to make a square cut.

But I didn’t, and it couldn’t. Since I know now what I didn’t know then, I recently fixed that.

I know this saw well. For more than 30 years I have cut all kinds of wood and never once hurt myself (well, at least not with this saw). And therein lies one lesson: when you have grown too comfortable with a power tool, it can hurt you.

The first time you use a powerful tool, the noise scares you enough to keep you alert. You know that you don’t know what you’re doing - and that’s a good thing because it helps to keep you safe.

For a long time afterwards, you maintain a healthy respect for the machine and you stay safe. Eventually, you become comfortable. Watch out.

Familiarity leads to complacency

Just behind that little square of plywood lay a 16" piece of 1x2" pine. Harmless stuff. Softwood. Left over from another project.

I pulled the RAS back on its arm. Made the desired cut on the plywood square. Never noticed the 1x2.

What happened next, as I reconstructed it later, probably occurred in less than 1/10 of a second: 100 Milliseconds. My only warning was a “chunk” sound - something out of place; something that I knew wasn’t right.

Subliminally, I also knew that my thumb had hit the saw blade. So I’m thinking, in the next 100 Ms: “What was that?, I’m just cutting a little piece of plywood.

And, Oh, something just happened to my thumb.” In retrospect, it’s interesting to review how we react.

Like most craftsmen (ok, craftspersons), I’m sure, I think I’m above average when it comes to safety. I read somewhere that 85% of all drivers consider themselves “above average”.

I have never operated the RAS without serious, industrial quality eye protection. I have always had a Shop Vac attached to capture sawdust and small chips.

In the last five years, ear protection has also been standard. Chain mail is optional, but useful when working with hardwood.

The saw rotates at 3450 RPM. The blade is 10" in diameter. The circumference of the blade is 31.4". The edge of the blade is travelling at 150 ft/sec. That’s about 220 mph.

Remember that piece of 1x2? When the saw completed its cut through the plywood, the teeth of the blade sunk into the leading edge of that 1x2 and launched it towards my left hand at 220 mph.

A few milliseconds later, my thumb hit the blade.

My first reaction was not to turn off the saw, but to turn off the Shop Vac, because it was making the most noise. Once it stopped, I realized that the saw was still running and turned it off.

My son, now 24, and his girlfriend, happened to be visiting my wife at the time. I went into the kitchen, wrapped my thumb in a paper towel to stem the blood flow, and calmly? (I thought I was calm) asked my son to drive me to the emergency room.

Later there was disagreement about whether I, or my son’s girlfriend, was more pale.

At the Emergency Room, if I had been badly hurt, I no doubt would have bled to death while I waited and filled out paperwork. Once that was done, all I really needed was a tetanus booster shot, some attaboys from a young nurse, some antibiotic goop and a good supply of thumb-friendly bandages.

The doc decided that stitches would not help, so a few Steri-tapes were employed, like miniature duct tape, to hold the loose piece of thumb in place. A little epoxy, kerosene, some white lithium grease (to prevent that annoying friction), and I was on my way home.

The nurse advised me that the loose piece of skin had very little blood supply and would not survive. She was right. Within a day, necrosis set in, and the soul of that little piece of my thumb left me.

I’m not sure whether it was headed up or down, but that would be useful to know for later reference.

What Did I Learn?

Remember that 1x2? It did not fare too well, either, but, being inanimate, it felt no pain, as far as I could discern.

Just to be sure, I whacked it with a hammer a few times; it showed no emotion. I suspect that, unlike my thumb, it has no soul. Now the careful observer will observe that the ends of the 1x2 are roughly hewn.

As craftpersons, this is not how we like the cut ends of our wood to look. This is how wood gets cut when it is yanked, suddenly, at 220 mph, into the saw blade without any backing board to hold it in place.

Moving at that speed, it can cause other side effects.

Do not leave stray materials on the saw table anywhere near the path of the saw blade

When I was a young lad, I often heard the aphorism: “If you fall off a horse, get back on and ride”. Applying this earthy wisdom to my current situation, I concluded that I should soon use my saw again so as not to develop an unhealthy fear of it.

And so I did. Immediately I felt my chest pelted by unfamiliar high-speed things. “This is not good”, I said to myself, and turned the saw off (this time before turning the Shop Vac off).

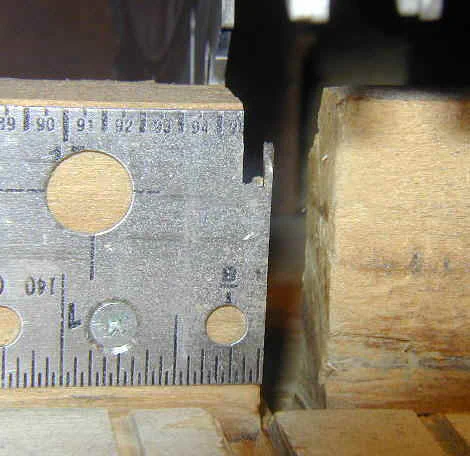

Careful examination of the obvious revealed that the pelters had been high-speed fragments of stainless steel, emanating from the ruler attached to the backboard.

The earlier incident with the 1x2 had shifted the position of the backboard. There’s a notch in the backboard for the saw blade to pass through which is normally aligned with the saw blade.

The backboard had shifted to the right about 1/4" so that the stainless steel rule was in the path of the blade. Apparently, the fragments had traveled around the rear of the blade, around the inside of the blade guard, and been launched out the front.

The carbide-tipped saw blade cut right through the stainless steel rule, sending little fragments my way. Well, at least I was wearing eye protection, or this could have been a more serious story.

After an “unanticipated incident”, carefully check your tool for damage, proper alignment, and proper operation before going back to work

Keep safe, boys and girls. This might be a good time to review the Safety Page. Two thumbs up for safety!