Spindle Wrench

If you own one of the mid-size mills such as the Sieg models X3, SX3 or SX4 or the Rong-Fu style mills, this new tool from Luminar Products may interest you.

These mills are sold in the U.S. and world-wide with various trade names, including Grizzly and Travers Tool in the U.S.

So, Luminar Products? Who are they? They’re a group of home machinists banded together by their common interest.

The company name is new, but one of the co-owners is a well-established innovator in the world of mini lathe and mini mills.

Ron Steele has developed and successfully marketed several well-known mini-lathe and mini-mill innovations such as the mini-mill belt-drive conversion kit, sold by our favorite purveyor of home shop tools, LittleMachineShop.com.

Tools such as these, developed by guys who love working with machines often fill a unique niche in the market.

On many of the mid-size bench mills, the spindle shaft is splined. In case all of this stuff is new to you, splines are ridges, spaced evenly around the circumference of a shaft, along some or all of its length.

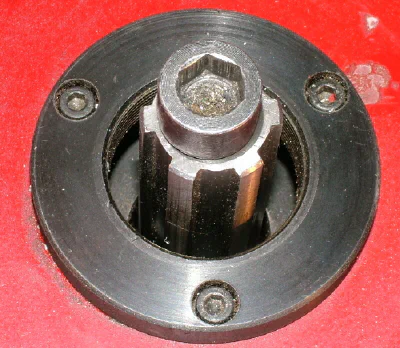

Splines on SX4 spindle shaft

Slots in Luminar spindle wrench slip over the top of the spindle shaft to mate with the splines. This arrangement provides a no-slip-grip and plenty of torque for removing those tools that are tightly locked into the spindle.

30 mm Luminar wrench

Splines transfer the power of the rotating shaft to a sleeve with matching grooves surrounding the shaft, while allowing the shaft to move up and down through the sleeve.

That’s how power is transferred to the mill’s quill while allowing the quill to move in and out of the head.

The wrench is available in two sizes. The smaller size has a 25mm end to fit the Sieg X3 and SX3 mills and a 28mm end for larger mills; the large wrench has a 25mm end and a 30 mm end, sized to fit the larger SX4 spindle.

25x28 and 25x30 versions of the wrench

If you own a mid-size mill, you no doubt already know how the spindle works, but for the benefit of less experienced readers, I’ll go into more detail.

The drawbar, which basically is just a long bolt, extends through the hole in the spindle and into the top end of the collet or end mill holder that holds the cutting tool.

When tightened snugly, the drawbar locks the tapered shaft of the tool holder into the corresponding taper inside the spindle, to prevent the tool holder from working loose from vibration or cutting forces on the tool.

To tighten or loosen the drawbar, the spindle must be held in fixed position. One way to do this is to use the so-called “fixing pin”. All of the milling machines made by Sieg, and resold under various brand names, use this method.

The pin is inserted into a shallow hole in the side of the spindle, just above the tool holder, and held with one hand while the drawbar is turned using a suitable wrench.

While not a problem on the mini mill, this method can become quite a stretch on a larger machine such as the SX3, the SX4 and the Rong-Fu style machines.

Especially for a guy like me, with relatively short, stubby arms, spanning the distance between the pin and the wrench on the large SX4 mill can be awkward.

Even more so, when I have to use a small stepladder to reach the drawbar wrench, as sometimes happens when the head is raised higher up on the column.

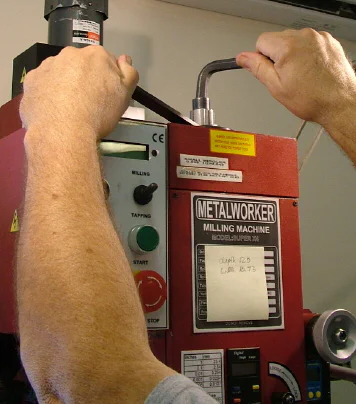

Stretching to tighten spindle on SX4 mill

That’s where the Luminar Spline Wrench really helps. Using the wrench to hold the splined shaft steady with your left hand, you tighten or loosen the drawbar with your right hand - or maybe using the opposite hands if you’re a lefty.

In any case, both hands, and their attached arms, are conveniently close together, making the whole operation easier, more comfortable and safer, especially when standing on a stepladder.

This is much more comfortable…

Additionally, the spline wrench provides a lot more torque than the short fixing pin, making it easier to loosen the drawbar when it’s acting stubborn.

You can get the smaller version of the wrench (25/28 mm) from LittleMachineShop.com or from Luminar Products web site, but I don’t yet see the newer and larger (25/30 mm) version listed yet. That should be available soon.

With the holiday season not far off, one (or both) of these would make a great stocking stuffer for the machinist in your life - even if that machinist is yourself.

;-)