Mini Lathe Tuning

There are several adjustments you can make to significantly improve the accuracy of your minilathe. These adjustments, properly done, can improve the quality of work you can produce.

To get accurate, nicely finished work and minimum chatter, it is important to remove as much play as possible in the saddle, cross-slide and compound.

Try grasping the compound and twisting it from side to side. If your lathe is properly adjusted you should be able to move it very little.

Adjusting the Gibs

One of the simplest and most effective adjustments is adjusting the gib screws. Gibs are metal strips that sit on one side of a dovetail slide, such as the cross-slide and compound, and which are adjustable to take up any slack or slop so that the dovetail slide is very smooth and snug.

Looking at the side of the compound rest you will see 3 small set screws surrounded by locking nuts.

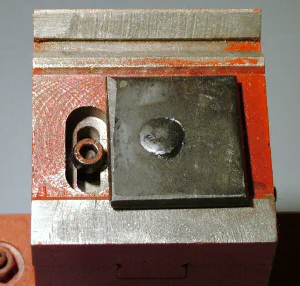

If you crank the compound rest all the way back until the compound lead screw disengages, you can then slide the top part of the compound free from the bottom part, exposing the lead screw, dovetails and gib strip.

Here’s a view of the underside of the top part of the compound rest.

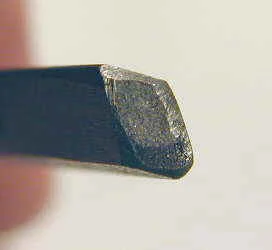

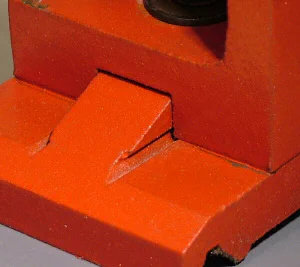

Viewed end-on the gibs are parallelogram shaped. On the back side of the gib you will find 3 indentations which act as engagement points for the adjusting screws.

Some owners have mistakenly thought that these indentations were manufacturing defects - they are not - they are there to hold the gib in place on the tips of the adjusting screws.

Look at the working face of the gib. As it comes from the factory these are usually pretty rough. Check my lapping page for information on how to polish this face to a shiny finish to get even more accuracy and smoothness from the dovetails. In the picture below, the gib has been polished.

While you have the compound removed, apply a light coating of white lithium grease to the gib face, the dovetail faces and the lead screw. White lithium grease is available from hardware stores in small plastic tubes which will last quite a while.

(Update 1/26/09)

I used WLG for a few years after I first got my lathe. Since then, I have switched to regular old automotive oil for lubricating most parts of the lathe.

The WLG still comes in handy for may other lubricating jobs, though.

With the compound back in place and positioned about midway in its range of travel, here’s the adjusting procedure:

- Use a 7mm wrench to slightly loosen each locking nut

- Start with the middle screw, grip the lock nut with a 7mm wrench and tighten the set screw using a 2mm hex wrench until the set screw is just snug.

- Back off the set screw about 1/4 turn

- Holding the set screw to keep it from moving, tighten the locking nut. The lock nut should not be super-tight, just tight enough to firmly lock the set screw in place.

- Repeat for the other two adjusting screws.

Now test the compound slide to make sure it moves smoothly. If you get the gib too tight it will lock the slide in place so don’t force the crank or you might strip the leadscrew.

Just repeat the above procedure but don’t tighten the gib screws quite so much. Try tightening the set screws slowly while you are cranking the compound back and forth and you can feel the gib start to snug up the dovetail.

This should give you a good sense of how tight the screws need to be.

You may have to repeat this procedure several times until you get a feel for it. As you use the lathe, the dovetails and gib will wear down a little over time so you will need to repeat this procedure periodically.

After you have the slide moving smoothly, try gripping the compound rest at either end and try to wiggle it side-to-side. There should be almost no play at all.

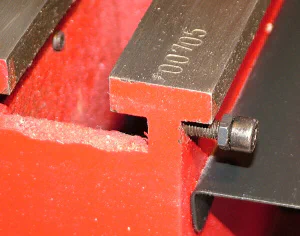

The procedure for adjusting the cross-slide is essentially the same. The gib screws for the cross-slide are on the tailstock side of the slide:

Adjusting Cross-slide Backlash

Grasp the cross-slide at either end and try to slide it back and forth. You will probably feel a movement of about .100 inches or more. By performing the adjustment described here you should be able to reduce this movement to about .

020 or less.

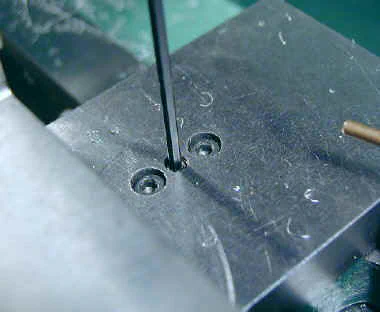

The cross-slide lead screw engages with a rectangular brass nut attached to the underside of the cross-slide by two hex screws. A third hex screw presses against the top of the brass nut to adjust its height.

By adjusting this middle screw and the two mounting screws, you can adjust the brass nut to minimize backlash in the cross-slide. It’s a crude mechanism, but it works.

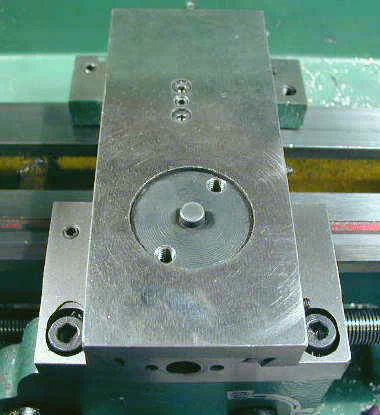

Here’s a picture of the underside of the cross slide showing the brass nut.

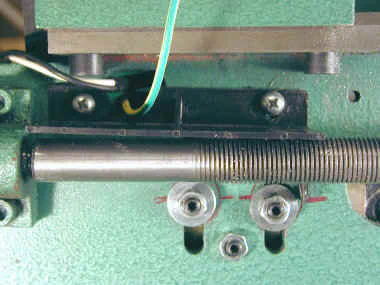

Here’s the lead screw:

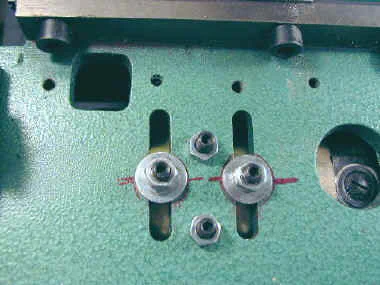

In the next photo you can see the three adjusting screws near the back end of the cross slide. The compound has been removed.

This shot shows a close-up of the nut removed and inverted so that you can see the arrangement of the adjusting screws.

Here’s the adjusting procedure:

- Loosen the two outer screws using a 3mm hex wrench

- Loosen the middle screw using a 2.5mm hex wrench

- Tighten the middle screw until it is just snug

- Tighten the two outer screws until just snug

Grasp the slide and slide it back and forth again. By alternately tightening the center screw and outer screws you can remove as much of the backlash as possible.

Like most adjustments on the mini-lathe, you need to play around with it a while to get a feel for it. Be careful not to overtighten the screws or you could strip the threads.

You don’t need to remove the cross-slide to adjust the backlash, but you may want to do so to lubricate the dovetails and leadscrew and to polish the gib strip.

The top of the cross-slide must be removed by sliding it off the back of the bottom section. One way to do this is to remove the splash guard. Alternatively, you can slide the saddle off the end of the ways.

Here’s an explanation of the procedure by Bruce Simpson:

> The two screws you talk about which “tighten” the cross-feed nut aren’t just there to secure it – they’re an adjustment designed to take up the slack. > > If you just torque them down then you will find the handle pretty hard to turn. > > The nut itself pivots on the center (flat-head) screw and the cap-head screws either side are their to tilt it. > > By tilting the nut you can progressively reduce the backlash. The goal is to obtain a degree of tilt that minimizes backlash without unduly increasing friction. > > You should adjust these screws with the cross-slide in the fully wound-in (i.e.: towards the rear of the lathe) position because it’s also possible to have the nut too high or too low which means it will bind on the feed screw when it gets to that end. > > Play around with the three screws until you get it right. > > The technique I use is to slacken the two cap-head screws and use the middle screw to set the height of the nut (so it doesn’t bind when the cross-slide is wound right to the back) > > Then slowly tighten one (doesn’t matter which one) of the cap-heads until you notice the slop starting to disappear. Once you’ve got the slack out you tighten the other one so that the nut is then firmly held. > > You’ll likely find that when you tighten the other cap-head screw that things free up a little and some of the backlash comes back – this means you may have to over-tighten the first screw a little in anticipation of this change. > > Another thing to watch is that you might need a shim behind the collar on the cross-feed screw where it presses against the cross-slide. It’s not uncommon to have quite a bit of slop here and the judicious use of some steel or brass shim cut into a washer shape can work wonders here.

Adjusting the Saddle

When you turn the carriage handwheel, the saddle should move easily along the ways without binding, but should be tight enough so that there is very little slop or play.

With the carriage about midway along the ways, grasp the carriage firmly and try to rock it back and forth. There should be very little movement if everything is properly adjusted.

Too much play will cause chatter during cutting operations and will make it difficult or impossible to get a smooth, clean cut.

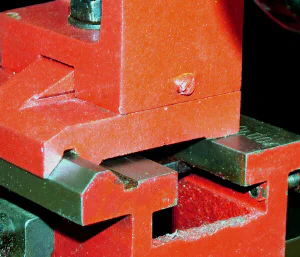

Look carefully at the gap between the lower edge of the saddle where it rests on the ways and the ways. If the gap opens and closes as you rock the saddle, there is too much play and you need to tighten the saddle adjusting strips.

The adjusting strips are two rectangles of fairly soft iron located on the underside of the saddle. There are three adjusting screws and two locking screws on each strip.

They are tricky to adjust properly, since you can’t easily get access to the adjusting screws while the saddle is mounted on the ways.

Therefore, you usually have to slide the saddle off the end of the ways, make a slight adjustment, remount the saddle on the ways and test and repeat this process until you get it right.

To make matters worse, the adjusting screws on the front side of the saddle are obstructed by the half-nut and the pinion shaft. (Note: you can avoid this painful procedure by doing my “Top Adjusting Saddle” Premium Content project)

When attempting to slide the carriage off the end of the ways to gain access to the adjusting screws, the carriage will sometimes stick at the end of the ways.

This is caused by the raised metal where the serial number is stamped onto the end of the ways. Use a file or sharpening stone and make a few light passes over the serial number to remove any raised metal.

The set screws with the lock nuts work to push the plates away from the bottom of the ways, while the three cap screws work to clamp the strips tighter to the ways.

The goal is to work these two sets of screws in opposition to each other until the guide strips are as snug as possible on the ways without causing excessive resistance.

Apply a little light oil along the surface of the ways and work the saddle back and forth. With a little work, you should be able to get the movement to be pretty smooth with very little slop.

Caution: the metal strips are brittle and will crack at the position of the set screws if you apply excessive force. Sooner or later this seems to happen to many lathe owners. I replaced the originals on my 7x10 with new ones I made from brass.

Here’s a procedure suggested by Bruce Griffing:

> I began by removing the saddle. I also removed the apron, though that is not necessary. On each side, there are 3 socket head cap screws and two adjusting screws. > > In this procedure, you remove the two end SHCS’s and don’t use them until the end. You begin by alternately loosening the center cap screw, adjusting the two adjusters and tightening the center screw until you achieve a 30 mil gap at both ends of the cast iron strip. > In this case the gap is measured between the iron strips and the saddle. I used a feeler gage to measure the gap. This should be done for both sides of the saddle. > > The next step is to loosen the center SHCS and put the saddle back on the lathe. Tighten the center SHCS and measure the gap between the ends of the strap and the underside of the ways. > > This should be done at both ends and on both sides. If the gap is zero, go back to the beginning and increase the initial gap to 40 mils. But it should be greater than zero, so record all 4 values. > > Remove the saddle again and do some math. If the gap with the ways was 12 mils then you want to reduce the saddle gap from the initial 30 mils to 19. This will reduce the gap with the ways to 1 mil - the target. > > This should be done for both ends of the strip - so it is a balancing act between the two adjusting screws. Once the correct gap is set at both ends of both sides, install all of the SHCS’s but leave them loose. > > Reinstall the saddle and tighten the center SHCS on both sides. If the 1 mil gap is correctly set, the carriage will move freely at this point. Then the end SHCS’s are adjusted to achieve the desired trade between rigidity and friction. > > At this point, you are bending the strips to close the one mil gap at each end. > > This method works very well and is much easier than it sounds. It minimizes stress on the strips and achieves good balanced retaining force.

It may be old news, but I haven’t seen it yet. One minor point - to do this you need some narrow feeler gages. I actually used shim stock to measure the strip to way gap.

Adjusting the Tailstock

The minilathe tailstock is made from two separate castings. The upper casting can be moved in or out, relative to the lathe centerline, to taper a workpiece, held between centers, along its length. For all other operations, the tailstock must be exactly aligned with the lathe centerline.

If it’s not, supporting a workpiece with a center in the tailstock, or drilling with a chuck in the tailstock will produce skewed results and possibly break drill bits. The tailstock can become misaligned due to rough handling during transport, by dropping the tailstock or by a previous use where it was offset for cutting a taper.

The upper casting can move along the raised area on the lower casting

The upper casting can move along the raised area on the lower casting

The upper casting is locked in position by a setscrew at the back of the tailstock and a socket head cap screw underneath the tailstock. If the setscrew at the back of the tailstock has never been removed before, it probably will be locked in place by paint.

Working it with a screwdriver that properly fits the screw slot should break the paint free, but be careful not to strip the slot or your problems will be magnified.

If the screw is really stubborn, a few drops of acetone, paint thinner or nail polish remover may help to soften up the paint locking the screw in place.

Set screw on back side of tailstock (sealed with paint)

Set screw on back side of tailstock (sealed with paint)

Cap screw under the tailstock base

Cap screw under the tailstock base

The screw underneath the tailstock can most easily be accessed by sliding the tailstock off the end of the ways. On some models of the minilathe, a stop screw, intended to keep the tailstock from accidentally sliding off the ways, may first need to be removed from the end of the bed.

Some mini-lathes have a tailstock stop screw

Some mini-lathes have a tailstock stop screw

To offset the tailstock, first loosen the set screw and the cap screw just enough so that the upper casting can be moved by tapping it with a light force.

I use the plastic handle of a large T-handle hex wrench like a soft hammer for that purpose, but depending on how tight the fit is on your minilathe, more force may be needed.

If you can’t get the upper casting to move, it may be sealed by paint. Here again, a small amount of acetone, nail polish remover or paint thinner may help loosen it up.

Once the tailstock is offset by the desired amount, tighten the two screws to keep the offset from shifting, but watch out - tightening the screws sometimes shifts the offset.

After completing the tapered cut, loosen the two screws as before and tap the upper casting as needed to bring it back in line with the lathe centerline.

One way to do this is to place a #3 dead center in the headstock and a #2 dead center in the tailstock and adjust the tailstock offset until the tips of the two centers are aligned as closely as you can get them.

An old machinist’s trick is to position a thin piece of shim stock, or a thin 6" machinist’s rule, no more than about .015" thick, held lightly between the points of the two centers.

A leaf from a set of automotive feeler gages, 0.005 - 0.015" thick, is also good for this test. If the centers are not lined up, the thin metal blade will tilt towards the headstock or tailstock.

Using a feeler gage to test tailstock alignment

Using a feeler gage to test tailstock alignment

In the photo above, the tailstock center is closer to the front of the lathe than the headstock center; the upper tailstock casting needs to be shifted a very small amount towards the back of the lathe.

When the two centers are exactly in line, the blade will be perpendicular to the lathe centerline.

Once that position is found, first tighten the set screw on the back of the tailstock and check to be sure that the alignment did not shift. If the blade is still perpendicular, carefully slide the tailstock off the back of the ways and then tighten the socket head cap screw underneath.

After tightening, recheck the alignment, as tightening the screw may shift the alignment. It may take several tries to get it just right.

Adjusting the Motor and Drive Belt

The motor is mounted on the back side of the lathe below the headstock. A toothed drive belt runs from a small toothed pulley on the motor shaft up to a larger pulley on the back end of the spindle.

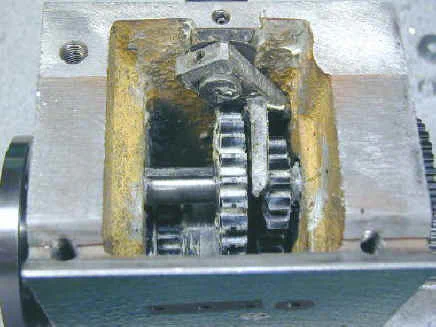

This is normally not visible since it is behind the gear assembly, but the assembly can be removed by means of two hex head cap screws located at the upper left and lower right corners of the casting.

It is not necessary to remove this cover to fix the belt alignment, but doing so will help you to see when the belt is properly aligned.

In the photo above, the belt is slightly misaligned. You can see that it is not properly centered over the upper pulley and is running pretty close to the side of the headstock.

The motor is canted slightly so that the left side is lower than the right side - this is probably why the belt is off center and leveling the motor will probably correct the problem.

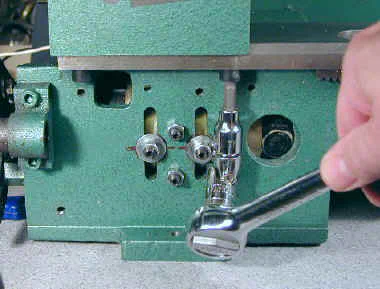

The position of the motor and the belt alignment and tension can be adjusted by means of the motor mounting bolts and positioning bolts. These are located on the front side of the headstock, behind the electronics box.

To get access to these screws, remove the black plastic shield above the leadscrew and the leadscrew. To remove the leadscrew,

- Remove the pillow block from the right end of the leadscrew

- Remove the gear from the left end of the leadscrew

- Remove the bushing and key from the left end of the leadscrew

- Slide the leadscrew to the right out from the pillow block on the left end.

Now you can get a better view of the adjusting screws.

The two bolts with the washers under the nuts hold the motor in place. Once loosened, it is easier to adjust these nuts with a 10mm nutdriver (or socket wrench) than with the open-end wrench that comes with the lathe.

The other two set screws push against the cylindrical motor housing and can be moved in and out to adjust the position of the motor. Moving the upper screw inward pushes the upper part of the motor back and tightens the belt.

Moving the lower screw inward has the opposite effect. As the motor is moved, the alignment and tension of the drive belt are changed.

When properly aligned, the belt should not touch any part of the lathe other than the two drive pulleys. To correct a problem with the belt rubbing against some other part of the lathe,

- Mark the original position of the motor mount bolts using a Sharpie pen

- Loosen the two motor mount bolts

- Loosen the alignment bolts

- Move the motor by hand until the belt appears to be properly aligned

- Tighten the mounting bolts finger tight

- Tighten the alignment bolts until they press against the motor housing

- Tighten the mounting bolts firmly

- Turn the lathe on at slow speed, check the belt and repeat until fixed.

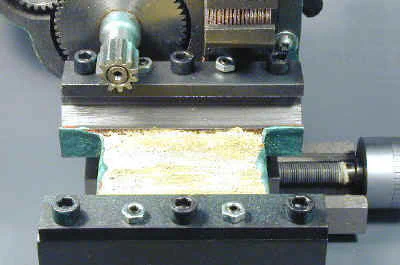

Removing and Lubricating the Headstock

The lathe spindle runs through the headstock supported at either end by precision thrust bearings. A keyed shaft runs through the headstock below the spindle and supports a large and a small plastic gear on either end of a common midsection.

This gear assembly is keyed to be driven by the shaft, but can slide along the shaft. The HI/LO lever moves a forked piece of metal which sits between the two gears, thus moving the gears from side to side along the shaft and engaging them with corresponding gears on the spindle.

Users who have ventured to look inside the headstock have generally found that there is little or no lubrication on the gears, shafts and levers. On my lathe, the HI/LO lever seized up after a few months of use, leading me to investigate the inner workings of the headstock.

Once you have gained some confidence disassembling and reassembling some of the basic parts of the lathe, it is a good idea to remove the headstock and thoroughly lubricate the moving parts with white lithium grease or similar lubricant.

Removing the headstock takes quite a few steps, and you should carefully set aside all the nuts and bolts as you remove them and keep track of where they came from.

The headstock is bolted to the lathe bed by three hex head cap screws which are very tight and are somewhat difficult to get at. These are best loosened by means of an 6mm hex wrench driven by a 3/8" socket wrench and flex-coupling.

Some owners have been able to remove them by using a hex wrench with a piece of strong tubing used as extension for extra leverage.

Here are the steps:

- Remove the leadscrew

- Remove the pillow block from the right end of the leadscrew

- Remove the gear from the left end of the leadscrew

- Remove the bushing and key from the left end of the leadscrew

- Make sure half-nut is disengaged (or remove carriage)

- Slide the leadscrew to the right out from the pillow block on the left end

- Remove the speed control box

- Unscrew ground wires from headstock casting

- Remove the black plastic guard above the motor mount screws

- Loosen and remove the two hex head cap screws securing the front of the headstock

- Remove the sheet metal cover from the motor in back of the lathe

- Loosen the motor mount screws and move motor aside

- Remove the single hex head cap screw securing the back of the headstock (in motor recess)

- Lift headstock casting off of ways.

Once you get the headstock off, use your finger or some kind of applicator to liberally spread grease on the moving surfaces. I recommend that you remove the HI/LO lever and lubricate the shaft where it passes through the side of the headstock.

I have never removed the main bearings or the spindle on my lathe. (Well, that was true when I wrote this years ago. Since then I’ve done it quite a few times.) I have avoided this under the assumption that their alignment is critical to the accuracy of the lathe. Here are some pictures on how to do this, sent to me by the Sieg factory.

Reassembly is basically just a reversal of the above steps but you will need to realign the motor mounts so that the drive belt runs freely.

The base of the headstock has a V-groove ground into it which mates with the ways to ensure proper alignment when the headstock is reinstalled, but make sure no chips or grit are on the base of the headstock when you reinstall it.