Motor Drive Controller Repair

On this page

In the early years of the mini-lathe, before 2002, the electronic speed controls got a reputation for having a high failure rate. Since then, Sieg has continually improved the design, so the new ones are much more robust than the originals.

Still, a sudden stall due to digging the tool into the workpiece, or some fine metal chips working their way into the electronics can cause even the new boards to fail.

And when your mini lathe or mill stops suddenly and won’t restart properly or runs only at top speed, you know it’s going to be a bad day in the workshop!

Sometimes it’s not the controller board itself, but another component such as the speed control potentiometer or a switch that fails, or just a loose connection. If you have a little electronics skill and experience, you can attempt to troubleshoot and repair the problem yourself.

LittleMachineShop.com has created an excellent troubleshooting guide that will help you sort out what’s wrong and sell replacements for the parts that fail most frequently. Often, the problem can be traced to the power MOSFETS.

If you, or a friend, has some soldering and circuit board repair skills, replacing the MOSFETs is a pretty quick and easy job. I’ve done it myself at least twice over the last 10 years.

A word of caution though: these boards and the surrounding electronics operate at around 100 volts DC, so be sure to observe electrical safety precautions at all times.

If you come in contact with the energized circuit, you may get a good jolt, but you could electrocute yourself, so be careful! Oh, and one more thing: don’t try to take a voltmeter or oscilloscope reading between the motor power leads and ground.

The power supply is floating, not grounded, and will immediately be fried! Don’t ask me how I know this.

If you’re not comfortable doing your own repairs, or you’ve already tried without success, you’ll need to send the board out for repair - and that’s where John Gerling, proprietor of Gerling Laboratories, can come to your rescue.

Many of you may know that, for years, Uncle Rabid, an active member of the Yahoo 7x10 lathe interest group, provided expert service repairing the controller boards.

Sadly, he passed away in March, 2009. He will be greatly missed by the mini-lathe community, both for the services that he provided, and for his great sense of humor.

It is timely, then, that Gerling Laboratories can take over this fine tradition.

Gerling Laboratories

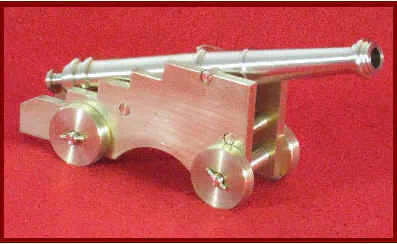

After retiring from a long and successful career as an expert in microwave electronics, John was looking for something new to keep him occupied. Never one to be short on ideas, John soon developed a beautiful project kit for making a brass cannon using the mini-lathe and mini-mill.

John used the cannon project to teach machine shop skills to interested folks at a retirement home in Oregon.

Still impatient, John was looking for an outlet for his electronics expertise. Familiar with the mini-lathe and mini-mill, he decided to look into starting a controller board repair business.

After exploring the possibility with me and some other guys familiar with the world of mini-lathes, John decided to give it a try.

Not one to dabble around, he first did a comprehensive study of all of the various types and models of controller boards. As it turns out, there are quite a few variations, so John had a lot of homework to do on that front alone.

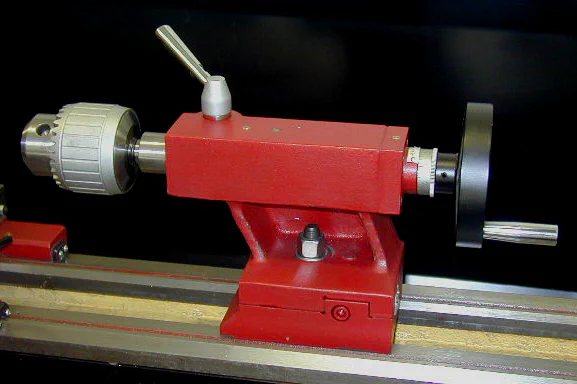

Next, he concluded that to be able to quickly diagnose and repair the boards at an affordable cost, some automation was needed, so he set out to build a special-purpose diagnostic tool.

Drawing on his extensive background in electronics, he built the test console shown below:

The test center enables John to evaluate each circuit board under closely controlled conditions. Testing may yield several possible outcomes:

- Operating normally; no repairs are needed

- Not functioning and is not repairable at reasonable cost (i.e. cheaper to replace it)

- Not functioning properly; one or more components need to be replaced and/or adjustments needed

Depending on the outcome of testing, John will repair the board and ship it back to you, or advise you that it can’t be repaired. If the board is not repairable, you can choose to have it returned to you or scrapped.

So, if your mini-lathe or mini-mill motor isn’t operating properly, get in touch with John at Gerling Laboratories. If the controller board can be fixed, he’ll fix it and get you back in operation.

If it can’t be fixed? Well, then you need to get a replacement board from LittleMachineShop.com. Just make sure you get the right type of board for your machine, since there are many varieties to select from.