Sieg Super X3 Mill

Sieg Super X3 mill

Sieg Super X3 mill

Recently arrived at mini-lathe.com World Headquarters is the Sieg Super X3 mid-size mill. I’ve been hearing about it on the internet for a while and was excited when the opportunity to test one emerged.

Well, it arrived recently, and I’ve had a chance to set it up, but have not done a lot of testing so far. Operations at mini-lathe.com & mini-mill.com tend to scale back during the summer months as I, and my readers, enjoy spending time outdoors with their families and friends.

So, to get the full scoop, you’ll have to come back again, say around the end of August, when I have more time to spend in the shop. But for now, here’s a small sample of what to expect…

There’s been some controversy on the web about the Super X3 being under-powered. I don’t have the full story on this, and there may have been some early models for which this was true, but the one I’m testing now seems to have plenty of power - even though the motor is fully enclosed in the head.

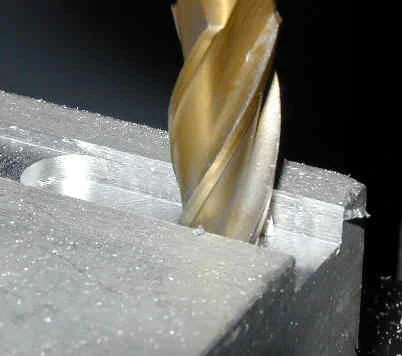

Take a look at this 0.100" depth cut using a 1/2" end mill - it powered through this test like a mole digging through soft dirt.

I did some more tests using a 3/4" 4-flute end mill on the same block of aluminum and found that a cut at a depth of 0.060" was no problem, while at 0.080" depth, the mill would whine and growl.

This does not seem to be a limitation in the power of the motor so much as reaching the stress limit of the spindle assembly, since I did not notice any tendency for the motor to bog down.

Since I have the Super X3 sitting side-by-side with the X3, I hope to do some comparison tests on power, as well as other features of the two models, and give you the full story.

What the two models have in common is their basic framework, including the base, column, X- and Y-axis controls and table. Where they differ is in the construction and features of the head assembly, Z-axis feeds, the motor and the control electronics.

And therein lies a a whole lot of interesting news. Take a look at the heads of the Super X3 and X3 below and you’ll get the idea…

Among the more obvious differences on the Super X3 are the following features:

- Digital RPM (tachometer) display with Forward / Reverse indicator

- Push-button membrane control panel

- Fine Feed control knob (similar to that on the mini-mill - only better!)

- Emergency Stop button moved from outboard box to front of head

- Power-on pilot light

- Digital Height Gauge continuously displays spindle advance

- Reverse and Tapping mode control buttons

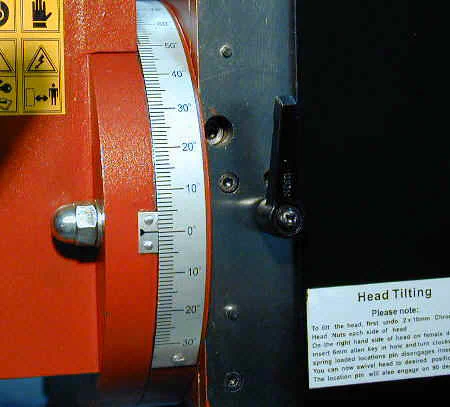

Of course you’ve already heard about the tilting head feature, right?

But what about those green buttons on the ends of the three-spoke handles? What’s that about?

Well, I hope that’s enough to stimulate your interest for now. Thanks for stopping by, and stay tuned for the full story!