LittleMachineShop.com Fixed Column Mini Mill

If you own a mini lathe or a similar small metal-working lathe, you may be looking for a small mill for making all of the kinds of “unround” parts that can’t be made on the lathe (* see footnote).

When you have both a lathe and a mill in your shop, the possibilities for what you can make are greatly expanded.

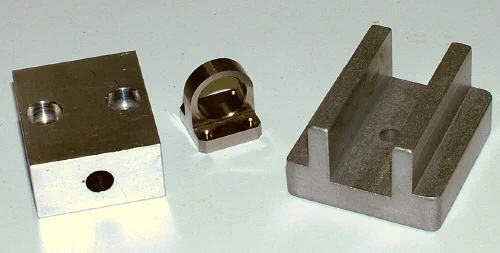

Typical parts made on a mini mill

Typical parts made on a mini mill

It’s been over ten years since I first wrote a comprehensive review of the mini mill back in 2002. Since that time the manufacturer has made a number of improvements and feature changes to this versatile home shop tool.

While the basic machine looks much the same as the older versions, the newer versions have greatly improved power, a quieter, more efficient and reliable belt-drive system plus a port for an add-on digital tach.

In this review, I’ll take an in-depth look at the latest version of the mini-mill as configured and sold by LittleMachineShop.com (LMS).

As regular readers of this site know, most of the mini mills and mini lathes sold by various vendors in the U.S. and worldwide are manufactured by Sieg Industrial Group in Shanghai, China. Sieg partners with retailers world-wide to provide custom combinations of features and color schemes so that each retailer can offer unique variants of the machines at competitive prices.

LittleMachineShop.com got its start back around 2000, as the foremost supplier of replacement parts for the mini-lathe, mini-mill and related machine tools made by Sieg.

Over the last 12 years, LMS has broadened their offerings to include a wide range of tools from top manufacturers including Starrett, Tormach and Irwin and they now sell just about everything that you might need to equip a top-quality home machine shop.

In the last few years, LMS also has started selling custom-configured versions of the mini-mill and mini-lathe manufactured by Sieg. Because the mini-lathe and mini-mill are at the very core of their business focus, LMS offers a level of expertise on these tools unsurpassed in the trade.

Well, that’s enough background, now let’s take a detailed look at the mini-mill.

General Construction

As with most quality machine tools, the primary structural component of the mini mill is cast iron. The head, table, column and base all are made from cast iron.

Cast iron is heavy and absorbs vibration, making the mini mill robust, and therefore more precise. This model has a larger table, longer base and thicker column than the standard mill and weighs about 125 lbs.

(56 kg).

Heavy cast iron base, column and table

Heavy cast iron base, column and table

One feature that sets this LMS version of the mini mill apart from the others is the non-tilting column bolted to the base for maximum rigidity.

Column bolted to base on LMS mini mill

Column bolted to base on LMS mini mill

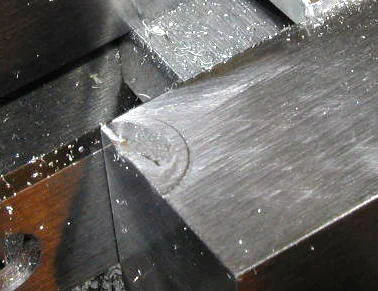

If you’ve worked with a mini mill before, or read about them on the internet, you probably know that in the standard design the column is mounted to the base by a large washer and nut, allowing the column to be tilted with respect to the base.

Traditional tilting-column attachment to base

Traditional tilting-column attachment to base

This seems like a useful feature, since it enables the cutting tool to be set at an angle to the workpiece to cut an angled surface. In actual use, though, it’s somewhat limited.

Except when near-vertical angles are involved, tilting the column shifts the position of the head towards one end or the other of the table, reducing the amount of usable table space and usable range of X-axis table motion as well as the amount of space between the spindle and the table.

Column tilted 30 from vertical

Column tilted 30 from vertical

When you’re done with the angled cut, you must carefully adjust the column to get it back in an exactly vertical alignment - a procedure called tramming - that typically takes at least 5-10 minutes.

Then there’s always the risk that the column may shift at some future time due to strong cutting forces or accidental impact, causing inaccuracies in the cut and possible damage to the workpiece.

If the shift is small enough that it’s not noticed, it may cause all future cuts to be out of square until it is discovered and corrected.

For these reasons, many experienced mini mill users align the column carefully, tighten it securely and then leave it permanently in the vertical position.

I recall one owner some years back welding metal plates between the column and the base.

For most situations where you need to make an angled cut, it’s more practical and easier to tilt the workpiece rather than the column. This can be done by holding the workpiece in a tilting vise, on a tilting table or by placing spacers under one side of the workpiece when clamping it to the table.

Recognizing these issues, LMS collaborated with Sieg engineers to develop this rigid-column model of the mini mill. I’ve worked with several mini mills over the last ten years and, in my opinion, LMS made the right choice on this feature.

Even so, there are some prospective owners who prefer the tilting column capability, so LMS also offers a tilting-column version as Model 3900.

There are, apparently, some operations that can be done with the tilting column feature but not with a tilting vise - I’ve just never run into such a situation in my shop.

Table

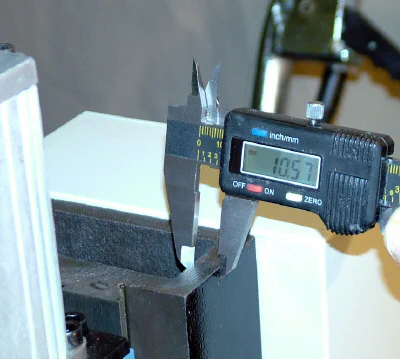

The table is longer and wider than the table on the standard mini mill and has longer travel in both the X- and Y- axes. (Note: measurements below do not include the end plates of the table.)

| Table Length | Table Width | Table X-axis Travel | Table Y-axis Travel | |

|---|---|---|---|---|

| LMS Mini Mill Model 3960 | 18.1" (460 mm) | 4.7" (120 mm) | 11.8" (300 mm) | 5.1" (130 mm) |

| Classic Mini Mill | 15.1" (380 mm) | 3.9" (100 mm) | 9" (230 mm) | 4" (100 mm) |

Extending along the front edge of the table, an inch scale, with zero at the midpoint, is helpful in centering work on the table and for measuring approximate table travel.

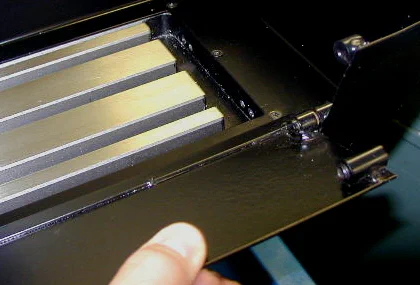

A rubber accordion-style cover helps to keep chips off of the dovetails and leadscrew.

Both the X- and Y-axes have locking levers to lock the table in place for maximum stiffness when the table is not moving in that direction. As with all the levers of this type on the mini mill, the clock-face position of the lever when it is locked can be changed by pulling out on the spring-loaded handle and resetting the lever to the position that is most convenient.

For smooth operation and accurate alignment, the table has adjustable dovetail slides in both the X- and Y- axis. Four set screws with lock nuts adjust pressure on the gib strip to minimize play while still allowing free movement of the table.

If you’re new to machine tools, a gib is a length of metal with a diamond-shaped cross section, typically made from soft steel, brass or bronze. The strip fits snugly into one side of the dovetail slide and can be adjusted to take up any slack caused by wear over a period of months or years.

Y-axis dovetail and leadscrew under the table

Y-axis dovetail and leadscrew under the table

Three grooved T-slots run the length of the table for convenience in clamping workpieces, vises, rotary tables and other work-holding accessories to the table. For most work on the mill, it is convenient to use a milling vise. Several styles are commonly used. For most of my work, I use a precision machinist’s vise.

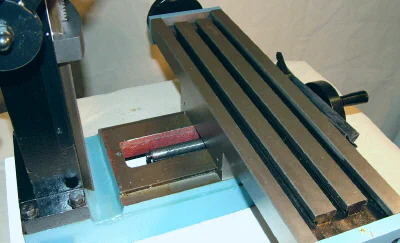

Precision machinist’s vise clamped to table

Precision machinist’s vise clamped to table

Unlike ordinary bench vises or drill-press vises, milling vises are machined parallel and square to accurate tolerances so that the work held in the vise is square to the table and mill spindle. They are very strong to resist the forces of milling operations. Workpieces also can be clamped directly to the table using components from a clamping kit.

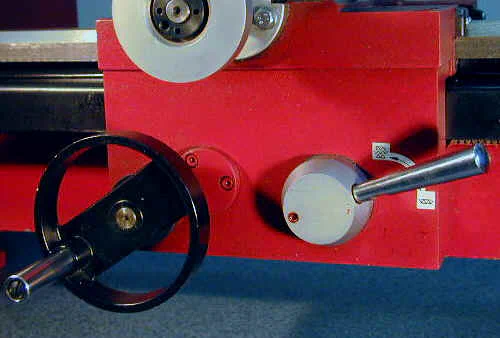

Movement of the table is controlled by a pair of solid cast handwheels about 4" (100 mm) in diameter. When the dovetail slides are lubricated with oil and the gibs are properly adjusted, the table moves easily in both axes with very little play.

The Y-axis handwheel is fixed to the base of the mill and does not move with the table; the X-axis handwheel is mounted to the right end of the table and moves with the table.

Y and X handwheels

Y and X handwheels

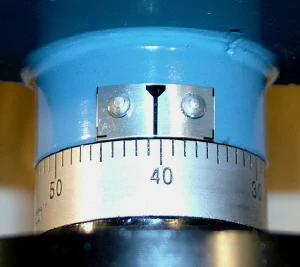

Both handwheels turn leadscrews with 1/16" (.0625") pitch, so the table moves 1/16" with each full turn of the handwheel, or 16 turns per inch. One consequence of that choice of pitch is that the calibrations on the handwheels look odd at first, since they have 62.5 divisions of 1/1000" of an inch.

Y- and X- axis graduated dials

Y- and X- axis graduated dials

Sharp black numbers and lines on a brushed finish are easy to read. The graduated dials can be zeroed by grasping and turning them while holding the handwheel steady.

Head and Column

The head houses the motor, belt drive and the rotating spindle. It rides up and down along the column on a large dovetail. The dovetail column keeps the spindle in a fixed vertical axis as the head is moved up and down the column, so the X- and Y- position of the cutting tool is maintained as the head is moved.

This is a nice feature. You can move the head down close to the workpiece to drill a pilot hole using a center drill, then raise the head up to insert a longer drill for the finished hole without losing the exact position of the spindle over the hole.

The sides of the column casting are about 40% thicker (10mm vs. 6mm) than on the standard mini mill, making it stronger and stiffer. This helps to reduce chatter and should make deeper and/or faster cuts possible than with the same size cutting tool used on the standard mini mill.

Extra-thick column walls (column cap removed for access)

Extra-thick column walls (column cap removed for access)

Coarse Control

In addition to milling operations, the mini mill serves as a very nice precision drill press. Key to this dual functionality is the rack-and-pinion drive mechanism.

A 3-spoke handwheel, like you’d find on a drill press, moves the head up and down the column.

3-spoke handwheel for coarse head movement

3-spoke handwheel for coarse head movement

However, on a drill press, and every other milling machine that I’m familiar with, the handwheel moves the spindle in and out of the head over a limited range, typically 3-4 inches.

By contrast, on the mini mill the handwheel can move the head over the full range of the column - about 10" (25 cm). That extra range of motion can be very helpful when drilling deep holes with larger diameter drills, but the real benefit is being able to quickly and easily move the head clear of the work area for changing drill bits or end mills while the spindle stays lined up with the workpiece.

The mini mill works so well as a drill press that I probably use it more often for drilling than for milling, even though I have a benchtop drill press nearby. It’s especially well-suited to precision hole placement, since the X- and Y- table handwheels can precisely position the workpiece under the spindle. With a DRO installed on the Y-axis (not included with the mill) it’s great for counterboring holes to a specific depth.

Fine Control

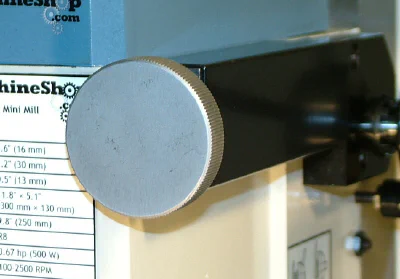

For milling operations, cutting tool depth needs to be adjustable to within one one-thousandth of an inch (0.001", .025mm) or better for precision work. A knob on the right side of the head provides fine-feed control.

Fine-feed knob

Fine-feed knob

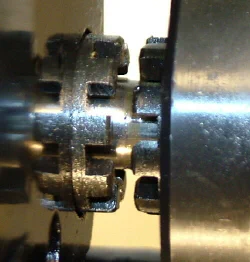

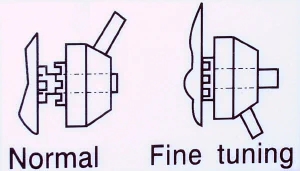

Fine-feed (“fine tuning”) is activated by pushing inwards on the 3-spoke handwheel to engage a pair of castellated cogs. With the cogs engaged, turning the fine-feed knob rotates the 3-spoke handwheel through a worm-gear arrangement.

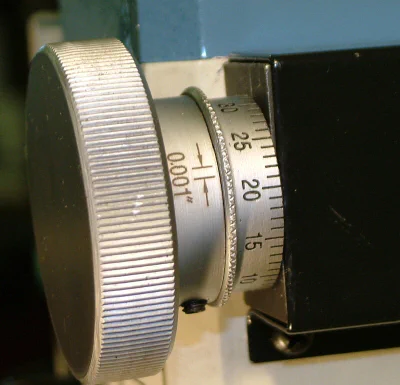

A rotating ring, calibrated in units of 0.001" measures the depth of the cut and can be set to zero by grasping the handwheel while turning the knurled grip on the calibrated ring.

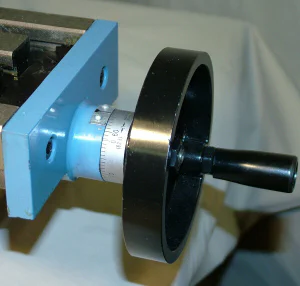

Calibrated fine-feed depth control

Calibrated fine-feed depth control

A tradeoff of this arrangement is that there’s quite a lot of backlash (~0.020 - 0.040") in the fine-feed knob. While this at first may seem daunting, you soon develop the habit of always starting the downward movement of the head well above the desired end-point. As the knob is turned to move the head down, the backlash is taken up and readings on the scale from that point on are accurate.

Inch Scale

An inch rule mounted on the left side of the column can be used for coarse depth measurements, such as when drilling holes, but, unfortunately, the motor control box blocks the view of the scale, limiting its usefulness.

Inch rule located on left side of column

Inch rule located on left side of column

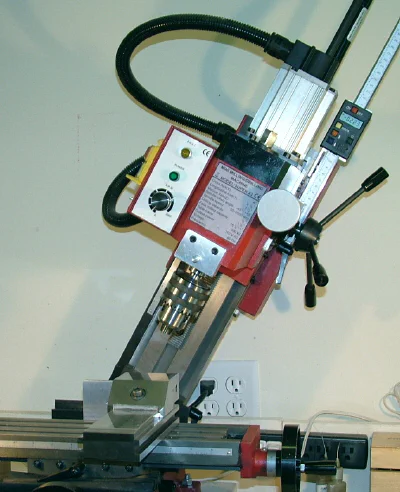

A much better solution is to install a vertical digital readout (DRO) on the right side of the mill. With careful use of the DRO, you’ll always know the exact depth of your cut.

You’ll have to make your own mounting brackets, but it’s well worth the effort. The DRO is easy to read, can be zeroed to the top surface of the workpiece and, as a bonus, lets you switch between inch and metric units at the touch of a button.

Here’s a photo of one that I installed on another mini mill.

After-market DRO installed on a mini mill

After-market DRO installed on a mini mill

Torsion Spring Arm

Like all of the mini mills that I’ve reviewed since around 2002, this one uses a coil spring and sliding arm to offset the weight of the head. As the head is lowered, the spring, enclosed in a cylindrical housing, is wound tighter, absorbing the downward force of the heavy head.

As the head is raised, the spring unwinds, offsetting the weight of the head to make it easier to move upwards.

Torsion arm on left side of column

Torsion arm on left side of column

Some early models of the mini mill, such as the one I bought from Grizzly in 2000, used a compressed-air spring to offset the weight of the head.

Air spring on 2000-model-year Grizzly

Air spring on 2000-model-year Grizzly

Personally, I like the air spring better than the torsion spring. It gives a more even supporting force over the range of movement of the head. For those who prefer it, you can buy an air spring conversion kit from LittleMachineShop.com to replace the torsion arm.

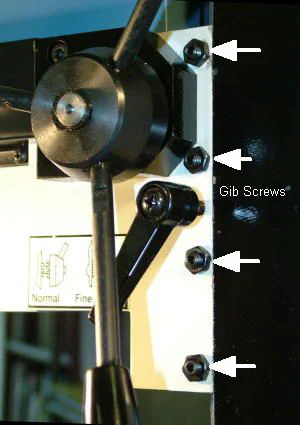

Gib Adjustment

A gib strip along the back right side of the head also helps control the movement of the head by providing friction between the head and the column. Four hex-socket screws with locking nuts apply pressure to the gib strip to tighten or loosen it.

Gib screws must be adjusted for proper head movement

Gib screws must be adjusted for proper head movement

When properly adjusted, the gib minimizes any play in the dovetail slide while still allowing movement of the head. For smooth motion and to prevent excessive wear, the dovetails should be kept lubricated with a thin film of oil or light grease.

I use ordinary 10W-30 motor oil.

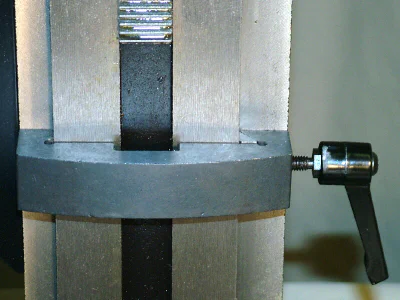

Locking the Head

During milling operations, the head must be securely locked to the column by tightening the locking lever below the 3-spoke handwheel, visible in the photo above.

The lock prevents the head from shifting position down the column due to vibration from cutting. For extra support, as when making an interrupted cut, the head stop can be moved up the column until it contacts the head, then locked in place.

he stop also is handy when you need to drill a series of holes all to the same depth.

Locking head stop

Locking head stop

Spindle & Chuck

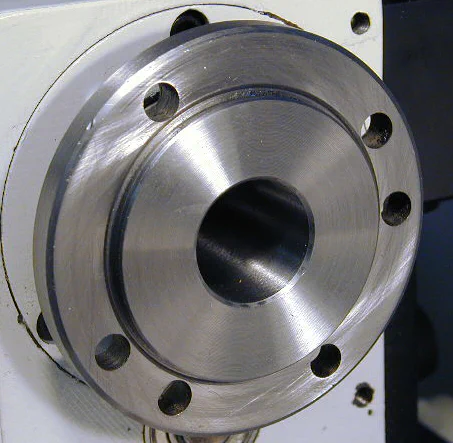

The mini mill is available from Sieg with two different spindle tapers: #3 Morse Taper and R8 Taper. This one uses the R8 taper which is the standard for mid-size Bridgeport-style mills.

Both types work equally well, but R8 accessories are more widely available and often are lower in cost than comparable MT accessories.

Morse Taper (upper) compared with R8 Taper (lower)

Morse Taper (upper) compared with R8 Taper (lower)

If you’re not familiar with tapers, they are used on machine tools for holding a rotating tool concentric with the spindle. When clean and free from dust, oil and metal chips, the inner and outer tapers mate tightly together and ensure that the cutting tool is accurately in line with the spindle.

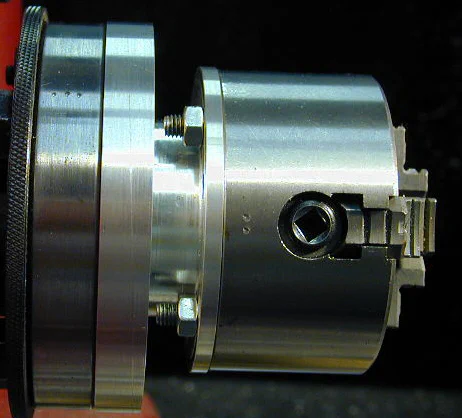

An R8 drill chuck arbor is included with the mill, but the chuck must be purchased separately, allowing the user to choose the type of chuck that best meets their needs; for example lower-cost versus higher quality.

The chuck-end of the arbor has a #33 Jacobs Taper (JT33).

R8 arbor with chuck in place

R8 arbor with chuck in place

A safety shield made from tough polycarbonate plastic is held in place on the front of the mill by a thumb screw and washer. To install the chuck arbor or other tooling into the spindle, the shield must be removed.

Removing the safety shield

Removing the safety shield

I strongly support having a safety shield in place during cutting operations, but the one that’s provided is not very practical.

Using the thumb screw to remove and replace it every time you need to change tools is a nuisance, and the shield gets in the way of many types of operations, encouraging the operator to just leave it off.

I’ve used other shields that I find more effective, including one you can make from instructions in my Premium Content section.

I’ve also found that a shield mounted on an articulating arm with a magnetic base to be effective and easy to move out of the way when changing tools.

End Mills and Holders

As good as it is for drilling, the real reason for having a milling machine is for milling. End mills are available in a wide variety of shapes, sizes and materials. End mills made in USA generally are of the highest quality but are much more expensive than imports. Starting out, the imports will do what you need and, if you damage them, they’re not so expensive to replace.

Various types of end mills

Various types of end mills

The flat spot visible on the shanks of some of the mills is called a “Weldon flat”. When used in an end mill holder (not a collet) the end mill is positioned so that the set screw tightens down on the flat.

As you gain experience using the mill, you’ll no doubt find that you need some of the more exotic types of end mills, but starting out, a basic set of 2- and 4-flute end mills, such as shown below, will take you a long way.

20-Piece end mill set - LMS PN 1244

20-Piece end mill set - LMS PN 1244

For milling operations, the end mill is held either in a collet or in an end-mill-holder (a.k.a. end-mill-adapter.) Both methods have pros and cons. You can buy inexpensive collet sets that will accommodate shank sizes from 1/8" to 3/4"; a good choice when you’re starting out.

R8-shank end-mill holders and collets

R8-shank end-mill holders and collets

Collets are less expensive and hold the end mill close to the spindle, saving a little bit of working space, which can be useful due to the mini mill’s limited headroom.

However, it can be tricky to install an end mill in a collet because the end mill must be held in place with one hand while tightening the drawbar with the other and using your third hand to keep the spindle from turning.

Due to the three slits in the face and sides of the collet, the steeply tapered part of the collet is springy. As the collet is drawn into the tapered spindle it clamps tightly and evenly around the tool shank.

In an end mill holder, the end mill is locked in place by a set screw. The end mill can be inserted either before or after the adapter is mounted in the spindle, but to avoid cutting your hand or possibly dropping the end mill, it’s safer to install it after the adapter is in place in the spindle.

When inserting an R8 collet or end mill holder into the spindle, the groove must line up with a drive pin inside the spindle. The pin prevents the collet from rotating while the drawbar is tightened or loosened.

The pin can’t normally be seen, but on most R8 mills that I’ve used, including this one, it is lined up with the small hole on the outside of the spindle, providing a handy reference point.

After you use R8 tooling for a while it becomes habitual to rotate the tool holder as you insert it in the spindle, until the pin drops into the groove.

Collet groove aligned with spindle hole

Collet groove aligned with spindle hole

Once inserted into the spindle, the collet is secured in place by tightening the draw bar at the top of the spindle. A safety cap covers the top of the draw bar when the spindle is rotating.

It is press-fitted in place and can be popped off by a gentle blow from the palm of the hand. Sometimes the fit is loose making the cap less effective.

Removing drawbar safety cap

Removing drawbar safety cap

With the collet (or other tooling) in place, the top of the draw bar is rotated clockwise by hand until the threads engage with the collet. Before tightening it, the end mill is positioned into the collet and held in place while tightening the drawbar snugly.

As a final step, the so-called “fixing pin” is inserted in the hole on the spindle and held in one hand to keep the spindle from rotating while tightening the draw bar using a wrench held in the other hand.

Sounds a little complicated, but soon becomes second nature. Not much force is needed on the wrench to lock the collet securely in place - be careful not to over-tighten.

Fixing pin holds the spindle while turning drawbar

Fixing pin holds the spindle while turning drawbar

To remove the collet from the spindle, reverse the above steps. After loosening the draw bar a turn or two, it may be necessary to tap the top of the drawbar with a small hammer to unseat the taper.

Use a brass- or soft-head hammer to avoid mushrooming the drawbar head. Keep your free hand under the end mill to catch it. If it falls onto the vise or table, the cutting edges may be dulled or chipped.

It’s a good idea to protect your hand with a shop rag or glove so that you aren’t cut by the sharp tips of the end mill.

Motor and Drive Train

The LMS mini-mill has a powerful 500-watt (about 2/3 HP) high-torque brushless DC motor. Highly efficient, this motor is small for the amount of power that it puts out and runs cool enough that it needs no ventilation holes or fan.

Therefore, it’s completely sealed from dust, dirt, oil and shop swarf - a feature that will likely mean a very long working lifetime.

If you’d like to learn more about brushless DC motors, the basics are covered in this Wikipedia article.

500-Watt Brushless DC motor

500-Watt Brushless DC motor

These motors run very quietly and are silent when stopped, since no cooling fan is needed. Such quiet operation is a real benefit if your shop is in a spare bedroom (or maybe your main bedroom ?!) and you’re working late into the night while others in the household are sleeping. (Like normal people. When I was younger, I often used to work in my shop until 1 or 2 AM.)

Though only about half the size and weight of it’s predecessor, this little motor packs a lot more punch.

Classic style motor on early mini mill from 2000

Classic style motor on early mini mill from 2000

The earlier motors have plenty of power at high speed, but have limited torque at lower RPMs, requiring a gearbox in the head assembly to reduce the spindle speed and provide more torque.

In the older design, virtually all milling operations were done in low range; the high range being used mainly for drilling small diameter (< 1/8") holes that require high RPMs.

HI-LO gear range selector on classic model mini-mill

HI-LO gear range selector on classic model mini-mill

A disadvantage of the earlier design is that the gear teeth between the motor and spindle could easily be broken if the cutting tool was advanced too aggressively into the the workpiece.

Not that it ever happened to me, of course, but I will admit to keeping several sets of spare gears on hand at all times, “just in case.” ;-)

Note: if you own one of the gear-drive mills, LMS sells a kit to convert it to belt drive - a big improvement!

In the LMS mini-mill, there are no gears; the spindle is driven by a toothed belt from the motor. Not only is this design more efficient in transferring power to the spindle, it’s more reliable and quieter since there’s no gear train inside the head.

The HI-LO gear range lever is gone and the full range of speeds is controlled directly from the motor speed control knob. Overall, it’s just a much better arrangement than the original.

Drive cover removed to show direct belt drive

Drive cover removed to show direct belt drive

A trade-off for the brushless motor is that both the motor and the electronics required to drive it are more expensive than for a conventional DC motor.

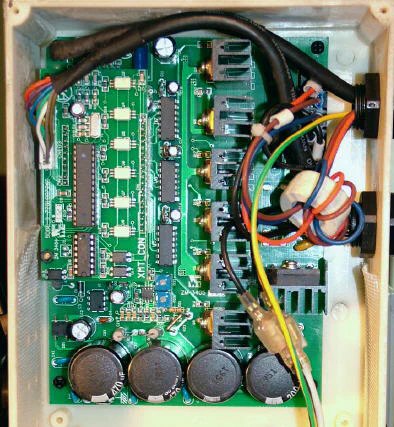

In a brushless motor, the phase of the magnetic field is controlled by electronic switching rather than by mechanical brushes. But, while the new speed controllers are more complex, they are excellent in quality, and, in my experience with them over the last few years, have been very reliable.

Mounted in a sealed box on the back side of the column, the controller board is well-protected from chips and fluids. Screened vent holes provide convective air flow.

Controller board for brushless DC motor

Controller board for brushless DC motor

Cables between the controller box and the motor and front panel are enclosed in tough, flexible plastic cable shields.

Flexible plastic cable shields

Flexible plastic cable shields

Electronic Controls

All of the electronic controls are located on a small box mounted on the left side of the head.

- Power On/Off switch and Emergency Stop

- Fault indicator lamp

- Power pilot lamp

- Speed control

Control box on left side of mill head

Control box on left side of mill head

The mini mill plugs into a standard 15- or 20-amp 120V outlet. Power is turned on by pressing the large green button on the side of the box and turned off by pressing the red button.

The red button also serves as an emergency stop button. It’s large and sticks out farther than the On button so that you can quickly mash down on it if something’s not right.

A thick clear plastic membrane covers the switches to keep out contaminants. On most versions of the mini-mill that I’ve used, the switches are enclosed by a hinged cover, but the cover is not present on this one, making the buttons more easily accessible.

Power OFF & ON buttons

Power OFF & ON buttons

Rotational speed for the spindle is set by turning the speed control knob, providing continuously variable speeds from zero to about 2,500 RPM.

Variable speed control really sets these machines apart from more traditional mills that require you stop the spindle and move belts between different sets of pulleys to select one of a few (usually six) fixed speeds.

On the mini-mill, you can change speeds between operations without stopping the motor, as for example to set a higher speed to make a shallow finishing cut on the workpiece - a great convenience and time saver.

Speed control knob

Speed control knob

It’s good practice always to turn the speed control knob to zero before stopping the mill. That way, when the mill is powered back on, the spindle will remain stopped until the speed control knob is advanced to the desired working speed.

On some previous models of the mini mill and mini lathe, that discipline was enforced by a switch built into the speed control knob, but the switch is not present on this model.

As on all the newer Sieg machines that have the brushless DC motors, the motor speed control is intelligent.

The controller provides electronic braking for the motor, bringing it rapidly to a stop when the speed control is turned to zero or the red Stop button is pressed.

If the motor becomes overloaded or stalled, the controller shuts off power to the motor, to protect it from overheating, and illuminates the Fault LED.

When a fault occurs, an internal relay is tripped, cutting off power to the motor. Once the condition causing the stall is cleared, the speed control is reset by pressing the green ON button.

Yellow fault LED

Yellow fault LED

The internal relay also trips if power to the mill is interrupted by a tripped circuit breaker or power failure. This feature ensures that the mill will not start back up unexpectedly when power is restored.

On the subject of power failures, I recommend having one or more emergency lights in your shop so that you aren’t left in the dark - possibly with a cutting tool spinning in the spindle - if a power failure occurs while you’re working.

On the back side of the control box are located the fuse holder and the plug-in port for the optional digital tachometer. When not in use, the port is covered by a rubber cap to keep out dirt, chips and shop fluids.

Tachometer port and fuse holder on back side of control box

Tachometer port and fuse holder on back side of control box

In the early models (before 2005) of the mini mill and lathe, stalling the motor by taking too deep a cut often would blow the fuse. Due to the much improved motor controllers in use now, I haven’t blown a fuse in years.

Digital Tachometer Option

An optional digital tachometer is available (PN 3818) for those who like to know exactly how fast the spindle is turning.

The tach plugs into a port on the back side of the control box and attaches magnetically to a metal plate at the top rear edge of the control box.

It displays the current spindle speed to within the nearest 10 RPM, which is precise enough for any type or work that you’ll do on this mill. While nice to have, it’s not really essential, and can certainly be deferred to a later purchase date if funds are limited.

Tach plugged into tach port

Tach plugged into tach port

When in use, the tachometer display plugs into the port and the connectors are secured by a threaded shroud. Magnets on the back of the tach housing hold the tach to a metal plate attached to the back of the control box.

Spindle rotational speed is displayed rounded to the nearest 10 RPM on the backlit LCD display easily readable from several feet away.

Digital tach display

Digital tach display

Accessories

As you unpack your LMS mini mill, you’ll find a plastic bag filled with parts and tools, including a set of metric open-end wrenches and hex wrenches for adjusting the mill.

The other parts include the draw bar, handles for the table handwheels, drill chuck arbor, plastic oil bottle, spanner wrench, spindle stop and two T-nuts.

Accessories included with the mini mill

Accessories included with the mini mill

One accessory that you’ll need right away is a drill chuck. LMS offers a range of chucks so that you can select one that meets your cost and precision requirements. Be sure to order a chuck with a taper that matches the included #33 Jacobs Taper (JT) spindle, though.

There are several other accessories, such as end mills, end-mill holders, a milling vise and parallels that you should plan to purchase at the same time as your mill. You can find some of my recommendations on the Mini Mill Accessories page.

LMS has a complete range of accessories available and provides a lot of useful tips on their web site to help you select the items you’ll need to get started.

Prior to starting up LMS, Chris Wood, the founder, was a technical writer. Not surprisingly, then, Chris wrote the 32-page user manual for the LMS mini mill.

The manual is thorough, well-written and illustrated with clear photographs and diagrams. Beyond the standard operating procedures, you’ll also find some tips, such as how to square a milling vise, how to use parallels and how to locate the edge of a workpiece - all things you’ll need to know to get started using your mini mill.

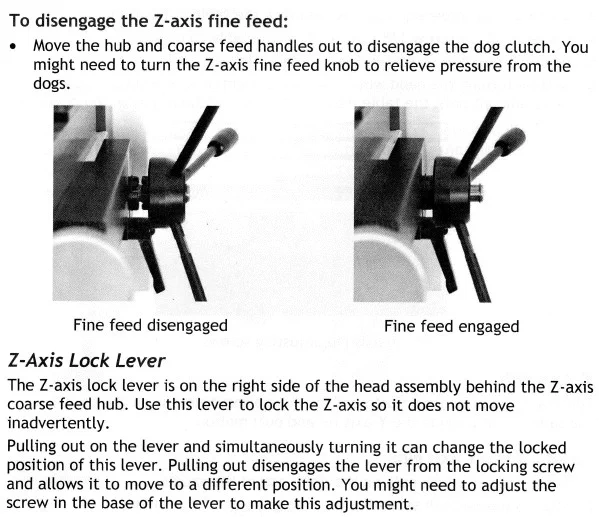

Here’s an example:

Power Feed Accessory

A power feed accessory for the X-axis is a great addition to any mini mill, but is especially helpful on this mill due to the longer table travel. Instead of wailing away on the X-axis handwheel, you can sit back in comfort and watch the power feed do all the work.

Not only is it quicker and a lot less hassle when cutting a long workpiece, but the finish is smoother due to the steady speed of the power feed.

The power feed kit is available separately from LMS as PN 4211. If funds are limited, this accessory makes a good future upgrade.

If you’re adventurous and have the time, you can make one from salvaged parts.

Add-on X-axis power feed kit.

Add-on X-axis power feed kit.

The two small blocks near the front of the photo are the left and right stops. They mount in the groove on the front of the table and contact micro switches to stop the power feed when the end of the table is reached.

The power feed controller has overload protection and stops the table if the movement of the table is obstructed.

Setup and Cleanup

Due to the extra large size of the table and thickness of the column, the LMS mini mill has a net weight of about 125 lbs. (56 kg.)

At that weight, you’ll definitely need a strong friend or some kind of lifting equipment to help you get it up onto the shop bench. It’s also over the maximum size and weight handled by UPS and FedEx, so it arrived by freight truck.

The truck driver unloaded it with a lift-gate and rolled it into my garage on a pallet jack. Well-protected by the crate and pallet, the mill was in perfect condition.

Shipping crate as delivered

Shipping crate as delivered

After some quick work with tin snips to remove the straps and a small crowbar to pry apart the sides and top of the box, the mini mill was exposed in full glory.

Not shown in the photo, the mill comes covered by a large plastic bag with some silica-gel packs enclosed to absorb moisture during shipping.

Mill bolted to pallet for shipping

Mill bolted to pallet for shipping

During twelve years of moving machines in and out of my shops in two different homes, I’ve acquired a variety of tools including shop cranes, ceiling hoists, [ramps and winches](https://www.mini-lathe.com/cust_mach/new_tools.htm#How to Move These Suckers) and hydraulic carts in my ongoing efforts to overcome gravity.

If you decide to go with one of these mechanical lifting aids, there’s no single best solution - you’ll need to do some thinking to figure out what will work in your shop.

Strong friends always are a good option, but it’s best not to break out the beer until the heavy lifting is safely completed.

Lifting onto hydraulic cart using ceiling hoist

Lifting onto hydraulic cart using ceiling hoist

Over the threshold and through the door…

Over the threshold and through the door…

After unpacking the mill from the shipping crate and getting it up onto a bench, the next order of business is to clean off the shipping grease.

Traditionally, Sieg machine tools have been shipped with a thick coat of soft red grease to protect the bare metal surfaces, such as the table, column and spindle, from rusting during transport and storage.

Removing the red grease from an older-model mini mill.

Removing the red grease from an older-model mini mill.

As much fun as I’ve had (?) cleaning up those machines, I’ve been happy to see that machines I’ve reviewed in the last two years have a thinner and lighter coat of grease, making the cleanup process quicker and easier.

Some kerosene or WD-40 and rags (pieces cut from old T-shirts work great) make quick work of the cleanup. Make sure you have good ventilation when you do the cleanup and be careful to keep volatile fumes away from sources of sparks and flames such as gas water heaters.

Recently I’ve begun wearing nitryl gloves during the cleanup process. I’m a slow learner, but eventually I catch on…

Cleanup is much easier on the LMS mini mill.

Cleanup is much easier on the LMS mini mill.

After removing the grease, you need to apply a thin coat of oil to all of the bare metal surfaces (to prevent rust) and moving parts (for lubrication).

Regular 10W-30 motor oil works fine for this, and is what I use, but there may be better alternatives available. LMS makes some recommendations in the mini mill user manual.

While it’s OK to turn on the mill for testing purposes without bolting it down, the mill must be securely bolted to a bench or baseboard for safe operation.

Recommended dimensions for the work area and the bolt holes are included in the user manual.

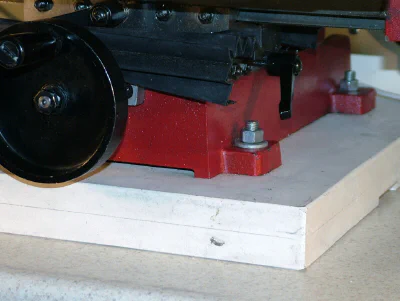

In some of my earlier installations, I bolted the mill directly to the benchtop, but in recent years, I’ve taken a different approach and bolted the mill to a base made from two pieces of 3/4"-thick MDF.

2-layer MDF base on another mini mill

2-layer MDF base on another mini mill

The base is very stable while still allowing the mini mill to be moved easily if needed and has the added benefit of raising the mill up off the bench top to provide more clearance for turning the Y-axis handwheel.

Warning: this solution is not safe if you have a tilting column mill and tilt the column away from the vertical position.

The column can only safely be tilted if the mill and the baseboard are securely bolted to a benchtop to prevent the mill from tipping over.

Conclusion

With thousands now in operation around the world, the mini mill is a proven tool for the home shop machinist and is an ideal complement to the mini lathe.

The basic design is sound, and the areas that have been troublesome, such as the drive gears, have steadily been improved or eliminated by the manufacturer.

The result is a very effective machine that can perform many metal-cutting operations that would be difficult or impossible to do any other way in the home shop.

LMS now has taken this improvement trend even farther by offering a rigid column option along with a longer table with extended travel in both axes.

While the larger table doesn’t make the LMS mini mill into a Bridgeport, it’s sure to help in those situations where the work is just beyond the range of motion of the standard table.

The fixed column provides maximum rigidity, for optimal cutting, while ensuring that the cutting tool remains properly aligned with the table and does not shift during heavy cutting operations.

If you compare mini mill prices and features from several vendors, you’ll find some that are less expensive, but keep in mind that not all are equal.

Some still have the older, lower torque motors and others, even with the newer motors, don’t have the larger, extended-range table and thicker column.

My recommendation is this: if you want to own the best mini mill currently available (August 2012), the LMS fixed column Model 3960 should be your choice.

Footnote

Strictly speaking, you can, in fact, make “unround” objects on a lathe, using one of these methods:

That said, it’s usually a lot more convenient to use a mill if you have one available.