Grizzly 6 Rotary Table

For some time now, I’ve been looking for a rotary table suitable for my Grizzly Mini-mill.

Choices seem to be limited pretty much to one of several 6" models available from various import suppliers such as Enco, J&L, Grizzly or Victor, or to the 4" Sherline.

I bought 6" model from Victor when it went on sale for $149, but the quality was so poor that I decided to return it.

I saw the Sherline at the Cabin Fever Expo 2001, and was impressed with its quality, but its small size and relatively light weight convinced me to order the Grizzly 6" version.

At approximately 20 lbs. the extra weight of the 6" model helps keep the work anchored to the table and can be expected to allow more vigorous cuts than would be feasible with a lighter version.

The Grizzly RT is shipped in a cardboard box with molded styrofoam packing. This makes it considerably easier to unpack than the Victor which was packed in a wooden box secured with nails, metal bands and corner braces.

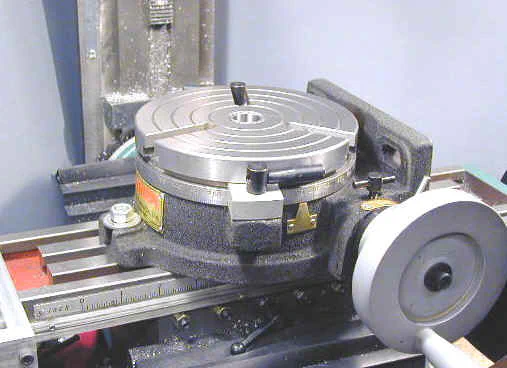

After cleaning off the packing grease with kerosene, a paintbrush and a rag, I mounted it on the mini-mill table using 3/8" carriage bolts that I also use for my 3 1/2" Grizzly milling vise.

The center hole is a #2 Morse taper.

The RT is really a little oversize for the mini-mill, but still provides enough clearance to be practical. I did not feel that the weight was beyond the capabilities of the mini-mill table.

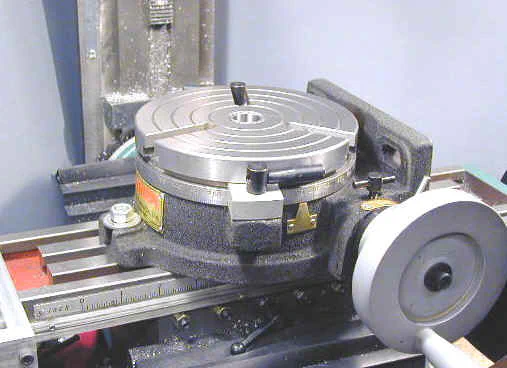

Here’s a picture showing the table with a 12" rule and a 1/2" mill in an end mill adaptor. Mounting the mill in a collet would provide another 2" or so of working room.

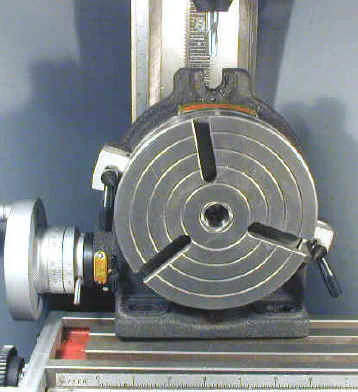

The head is at the top of the column. Also shown is the 3" chuck from the 7x10 mini lathe. As you can see, there is adequate clearance for most operations.

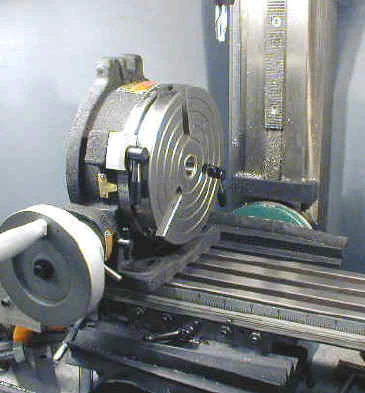

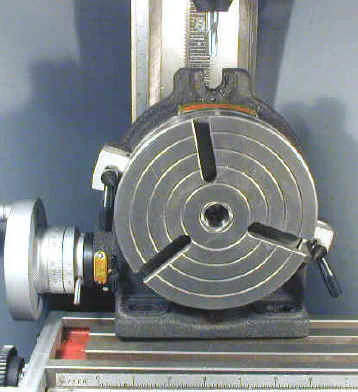

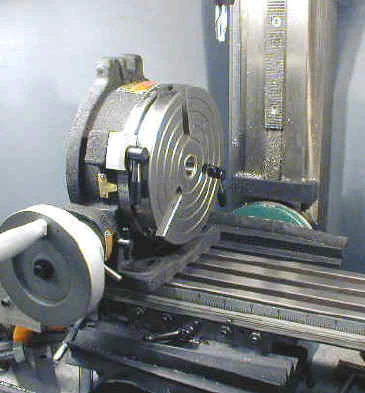

While the Victor is intended only for use in a horizontal mounting, the Grizzly casting has mounting lugs for both horizontal or vertical mounting. This makes it potentially much more flexible, but the table of the mini mill is small compared to the RT which makes mounting the rotary table in the vertical orientation a little more problematic.

It can be aligned either parallel or perpendicular to the table x-dimension but either orientation has some difficulties.

One problem is that the lower edge of the handwheel for the RT is lower than the base of the RT, so it must be positioned off the edge of the table. If the RT is positioned perpendicular to the X-axis, the mounting holes in the RT are outside the limits of the T-slots in the mill table.

These problems can presumably easily be overcome by using custom-made riser blocks and clamps, though. I have not yet attempted to make these items, but would not expect them to be very difficult to make.

For the price, I was pretty impressed by the quality of the table. I would rate it somewhat lower in quality than the Sherline 4", but much better than the Victor 6".

The base is painted with wrinkle-finish black paint. Fortuitously, the T-slots in the RT are about the same width as those on the mini-mill, so the same T-nuts can be used on both.

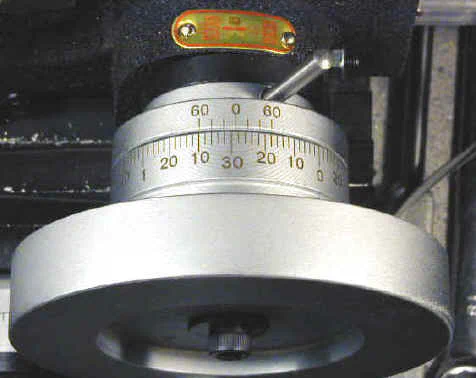

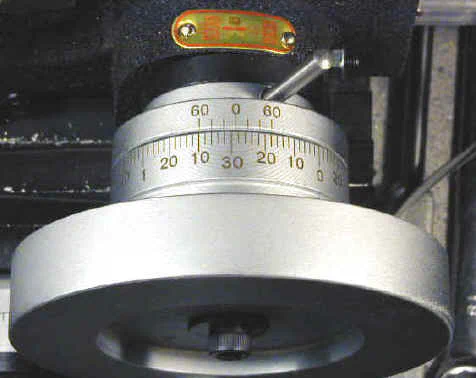

The handwheel is satin-finish steel with cleanly etched divisions. Each full rotation of the handwheel rotates the table by 4 degrees. A brochure included with the RT illustrates an indexing plate accessory which can apparently be attached to the RT, but I’m not sure whether or not Grizzly sells this accessory.

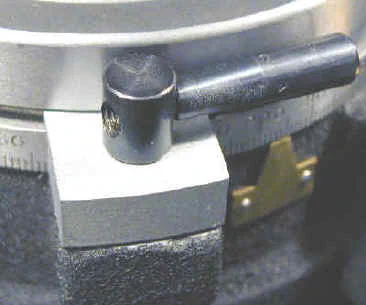

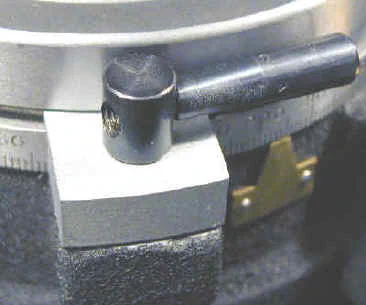

An eccentric cam between the handwheel and the table permits you adjust the meshing of the worm-screw to minimize backlash. A screw with a T-handle locks the cam in place once it is set.

Here’s a closeup of the divisions on the periphery of the table before the packing grease was removed.

Once rotated to the desired setting, the table can be locked in place by means of two locking clamps on opposite sides of the table.

I have not yet had time to put the RT through its paces, but I’m pretty happy with the quality and expect it to be a valuable addition to my shop.

models available from various import suppliers such as Enco, J&L, Grizzly or Victor, or to the 4" Sherline. I bought 6" model from Victor when it went on sale for $149, but the quality was so poor that I decided to return it.

I saw the Sherline at the Cabin Fever Expo 2001, and was impressed with its quality, but its small size and relatively light weight convinced me to order the Grizzly 6" version.

At approximately 20 lbs. the extra weight of the 6" model helps keep the work anchored to the table and can be expected to allow more vigorous cuts than would be feasible with a lighter version.

The Grizzly RT is shipped in a cardboard box with molded styrofoam packing. This makes it considerably easier to unpack than the Victor which was packed in a wooden box secured with nails, metal bands and corner braces.

After cleaning off the packing grease with kerosene, a paintbrush and a rag, I mounted it on the mini-mill table using 3/8" carriage bolts that I also use for my 3 1/2" Grizzly milling vise.

The center hole is a #2 Morse taper.

The RT is really a little oversize for the mini-mill, but still provides enough clearance to be practical. I did not feel that the weight was beyond the capabilities of the mini-mill table.

Here’s a picture showing the table with a 12" rule and a 1/2" mill in an end mill adaptor. Mounting the mill in a collet would provide another 2" or so of working room.

The head is at the top of the column. Also shown is the 3" chuck from the 7x10 mini lathe. As you can see, there is adequate clearance for most operations.

While the Victor is intended only for use in a horizontal mounting, the Grizzly casting has mounting lugs for both horizontal or vertical mounting. This makes it potentially much more flexible, but the table of the mini mill is small compared to the RT which makes mounting the rotary table in the vertical orientation a little more problematic.

It can be aligned either parallel or perpendicular to the table x-dimension but either orientation has some difficulties.

One problem is that the lower edge of the handwheel for the RT is lower than the base of the RT, so it must be positioned off the edge of the table. If the RT is positioned perpendicular to the X-axis, the mounting holes in the RT are outside the limits of the T-slots in the mill table.

These problems can presumably easily be overcome by using custom-made riser blocks and clamps, though. I have not yet attempted to make these items, but would not expect them to be very difficult to make.

For the price, I was pretty impressed by the quality of the table. I would rate it somewhat lower in quality than the Sherline 4", but much better than the Victor 6".

The base is painted with wrinkle-finish black paint. Fortuitously, the T-slots in the RT are about the same width as those on the mini-mill, so the same T-nuts can be used on both.

The handwheel is satin-finish steel with cleanly etched divisions. Each full rotation of the handwheel rotates the table by 4 degrees. A brochure included with the RT illustrates an indexing plate accessory which can apparently be attached to the RT, but I’m not sure whether or not Grizzly sells this accessory.

An eccentric cam between the handwheel and the table permits you adjust the meshing of the worm-screw to minimize backlash. A screw with a T-handle locks the cam in place once it is set.

Here’s a closeup of the divisions on the periphery of the table before the packing grease was removed.

Once rotated to the desired setting, the table can be locked in place by means of two locking clamps on opposite sides of the table.

I have not yet had time to put the RT through its paces, but I’m pretty happy with the quality and expect it to be a valuable addition to my shop.