Review: Grizzly 7x12

Introduced in Fall of 2001, the Grizzly 7x12 offers several benefits over the 7x10 versions of the same lathe that have been available until now. Besides the longer bed length, about which I will say more below, Grizzly supplies several accessories with the new 7x12 that are not provided by with the other lathes.

The power supply is also much improved, providing low speed with good torque right out of the box. You won’t need to tweak the motor controls as we used to have to do with the 7x10 models.

7x12 Versus 7x10

I have had my Harbor Freight 7x10 mini-lathe for over two years now and have been pretty happy with it. I am an inventor and experimenter and I use the lathe mainly for making special parts for devices that I am experimenting with.

Most of these parts are fairly small and short, so the 7x10 has sufficient capacity for most of my needs. Because of the short bed, though, the 7x10 can’t drill into the end of a workpiece longer than about 4" if the diameter is greater than 3/4" and will not pass through the spindle.

This has been a limitation on several projects, and has led me to move up to the Grizzly 7x12.

Despite its 7x12 designation, the 7x12 actually is nearly 4" longer than the 7x10. This provides extra room to move the tailstock out of the way when it is not in use and allows for drilling and turning longer stock.

Additionally, the Grizzly 7x12 has a better power supply than the HF 7x10 (or at least the older model that I have). The 7x12 has very low speed with excellent torque right out of the box, obviating the need for the low-speed mod most of us have made to the 7x10.

The power supply also has an interlock that requires you to reset the speed to zero before restarting, thus preventing the lathe from starting up at high speed.

This feature also prevents blowing fuses by accidentally switching from forward to reverse while the lathe is running. The overall fit and finish of the Grizzly is a little better than the HF 7x10.

Other than that, the lathes are pretty similar and most of the parts and accessories are interchangeable.

Receiving and Unpacking the 7x12

I ordered the 7x12 from the Grizzly web site on 9/15/01 - the last day of the summer sale. Ordering from the web entitles you to a free gift based on the dollar amount of your order.

Grizzly has a wide selection of gifts, and some of them are pretty decent, making the web ordering process a good way to go.

When I ordered my Grizzly 7x12 back in 9/01, it was shipped by truck freight. It is my understanding that they are now all shipped by UPS.

Generally the UPS driver will meet you at the door of your home or, if it is safe to do so, just leave the box on your porch or garage entryway. The box weighs around 90 lbs.

, so unless you are pretty strong, you’ll need a hand truck, wagon, or a strong friend to help you move the lathe into your shop. Fortunately, my shop is in my garage, so it was a short haul up the driveway into the shop, which was accomplished quite easily with the help of a cheap luggage cart.

The Grizzly 7x12 is packed in a molded styrofoam shell inside a cardboard box. From reports I have seen on the 7x10 interest group, this packing method seems to do a better job of protecting the lathe.

Nevertheless, one corner of the chip tray was bent - a common occurrence from what I have heard. This was not a big deal to me, since I will mount the lathe directly to my bench and will not use the chip tray.

I’m sure that Grizzly will replace it under warranty if I ask them to.

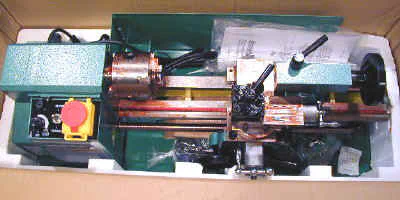

When you open the box, it looks like this:

The large round object is the faceplate covered with red packing grease and wrapped in plastic. It had migrated from the molded slot in the styrofoam to the left, but this did not cause any problems.

Other accessories are tucked in molded slots.

Removing the top layer of the styrofoam packing reveals (drum roll…) the lathe. Like the faceplate, the lathe is covered in red grease and wrapped in plastic. Removing the plastic sheet gives a better view of the lathe and grease.

The lathe was in excellent shape, but did have some minor damage to one corner of the chip tray. This is apparently quite common as I have heard a number of owners report the same thing.

I did not notice any damage to the shipping container until after I opened the box and saw the bent corner of the tray. A retrospective examination of the box revealed an accordion-like compression on the damaged corner.

I know from the experience of others that Grizzly would have cheerfully provided me with a replacement chip tray if I had requested one, but it made no difference to me since the method I use to mount the lathe does not use the chip tray at all.

Cleaning up the Lathe

Kerosene is my preferred solvent for cleaning up the red gunk that covers the lathe. It does a great job of dissolving the stuff and is fairly safe to work with indoors.

It’s best to work with it in a well ventilated area and avoid sparks or flame including possible sparks from nearby motors (such as when testing the lathe!) or pilot lights from furnaces, etc.

A little goes a long way and a quart would probably be more than enough to clean up the lathe.

I pour about a pint into a plastic pail and clean small parts right in the pail. I use 2" or 3" ‘chip brushes’ dipped in the pail to paint kerosene onto the larger lathe parts such as the bed and the chuck and then use rags to wipe of the red grease and kerosene.

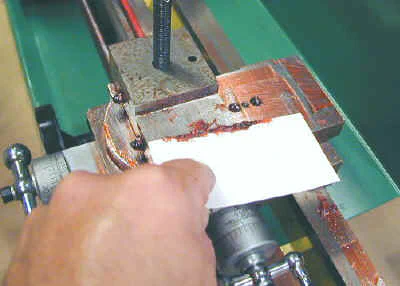

I used some old business cards to scrape off the thick layer of grease before going at it with the kerosene.

Use a card, brush and rag to clean off most of the grease from the chuck. To thoroughly clean the chuck, remove it from the spindle and use a brush to clean it up in the kerosene bucket.

The retaining nuts on my chuck were very tight, so I inserted the chuck key and grasped it tightly to keep the chuck from rotating while I applied pressure to loosen the chuck retaining nuts.

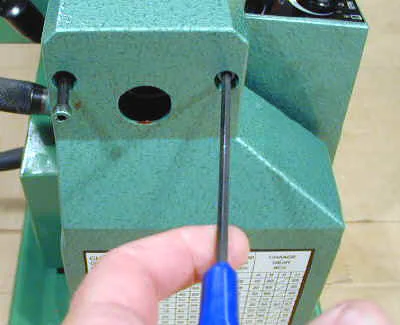

Use a 4mm hex wrench to remove the two cap screws that hold the gear train cover in place. Then lift the cover off to expose the gear train for cleaning.

Clean up the gear train using a brush and rag. To do a more thorough job you can remove the gears and clean them up with the brush in the kerosene bucket.

After reassembling, apply a light coat of white lithium grease to the gear teeth. This will keep them running smoothly and will make them quieter when using the power feed.

Now you can access the two 6mm hex head bolts that hold lock the cross slide at a specific angle. Remove these two screws and lift the compound slide off of the cross slide.