Machine Shop Essentials

On this page

Let me get right to the point: I really like this book!

If you’re just starting out in machine shop work, or you need a refresher course, you will find this book to be an excellent tutor. It covers all the basic machine shop tools and techniques from hand filing through advanced lathe and milling techniques.

It will teach you about all the parts of the lathe and mill; not just the names of the parts, but what they do and why, along with some interesting historical notes.

At 500+ pages, this book should keep you occupied for some time, but the text was easy to absorb, and I found myself reading on and on, into the early morning hours.

Most books put me to sleep within minutes, but not this one. There’s so much good information that I just wanted to keep going.

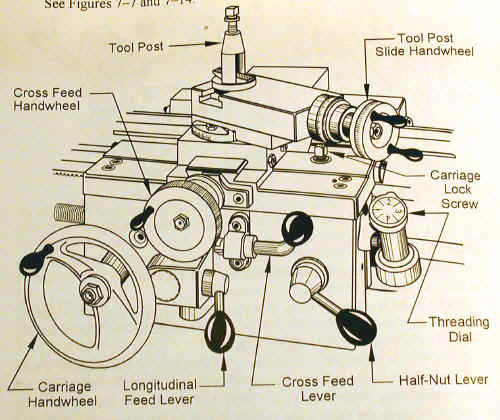

Just about every one of the approximately 500 pages of the main body features one or more beautifully executed line drawings by Pamela J. Tallman. These drawings not only illustrate the concept at hand, but are pleasing to look at for their own sake.

If you like machinery and tools (and I doubt if you would be reading this if not) you should find these illustrations very enjoyable.

Format and Content

The chapters follow a logical progression, starting with basic concepts such as measurement and hand tools, and work their way on to more advanced topics including turning operations and milling operations.

Chapters 9 through 12 then cover several other areas of shop practice such as safety and tool sharpening. Here’s a summary of the chapters:

1 Measurement Tools, Layout & Job Planning

2 Basic Hand Tools

3 Filing & Sawing

4 Grinding, Reaming, Broaching & Lapping

5 Drills & Drilling Operations

6 Threads & Threading

7 Turning Operations

8 Milling Operations

9 Fastening Methods

10 Machine Shop Steel Metallurgy

11 Safety & Good Shop Practices

12 Other Shop Know-How

Appendix I Sharpening Steel Lathe Tools

Appendix II Sources of Tools, Materials & Supplies

Like any good instructor, the author holds your attention by posing questions throughout the text. In fact, much of the text other than the chapter introductions follows this format.

For example:

> What tools are used to cut internal threads?

>

> There are two common types of tools:

>

> Commercial boring bars with either HSS, alloy steel or tungsten carbide tool bits are the most common.

>

> For holes too small for a boring bar, an HSS tool bit blank may be ground into a small, single-piece threading tool. These are also commercially available.

See Figure 7-146.

I actually had to search through the book to find a fairly short example. In most cases the answers are very extensive. If you study this book for a while, I would imagine that you would be well-prepared to pass a test in introductory machine shop practice at a technical college.

Just to give you a little more of the flavor of the book, here’s a longer excerpt:

Other Threading Methods

> What other methods are used to apply male threads and what are their advantages?

>

> Roll Threading presses a hardened steel die with the desired thread form against a rotating fastener blank.

As die force increases, the thread profile transfers to the fastener. This process produces stronger, more fatigue-resistant fasteners than machined threads because its cold working does not disrupt the blank’s grain structure, Figure 6-31.

For screws and bolts up to 1-inch diameter, heads and threads are cold-formed. Larger bolts and high-strength screws have hot-forged heads and cold-rolled threads.

Threads are cut or tapped only on fasteners which are too large for thread rolling. > Grinding Threads offers high accuracy, the ability to machine hard materials, and a smooth thread finish.

Precision measurement tools, gages and master threads are frequently ground. Most threading taps and micrometers have ground threads. > Lathe Threading with single point tools is covered in Chapter 7 - Turning.

One of the things I like best about this book is that it does not just teach theory, but gives practical instructions and illustrations. The best way to illustrate this is to show a sample page:

![]()

I apologize for the distortion of the page, my scanner is currently out of commission, so photographs will have to do.

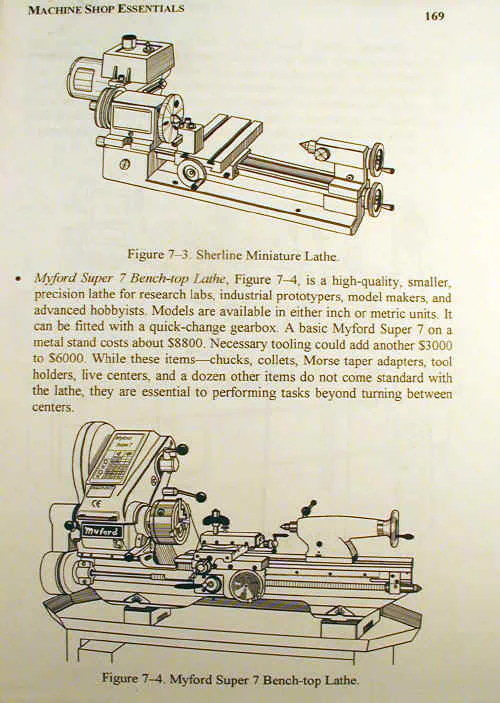

Another feature of this book that makes it particularly valuable to the hobbyist, is that it does not deal exclusively with industrial-size machines. In fact, throughout the text and illustrations, Sherline-brand lathes, mills and accessories are used to illustrate how the principles under discussion apply to the small home shop.

On the larger end of the scale, you’ll find examples of Myford, Logan and Clausing lathes, and an entire section that pretty much teaches you how to run a Bridgeport (or Bridgeport-style) vertical milling machine.

Conclusion

At $44.95, this is not an inexpensive book, but it is a good value. Having done some writing myself, I fully appreciate the long hours of effort that go into producing a book of this depth and quality.

Then of course, there are the years of study, training and practice that the author must put in to be qualified to write such a book. Put in that perspective, this book is a real bargain.

With gas prices going the way they are, this book may soon cost less than a tank of gas. And in the course of your career or hobby, it will take you a lot farther. (Update: 2/18/08 Just filled up my tank for $51. Guess I called that right!)

Here are some places you can buy it online:

- Metal Arts Press

- LittleMachineShop.com

- Guy Lautard’s site (I also highly recommend Guy’s Machinist’s Bedside Readers, check ’em out)

- The Sherline site

- Victor Machinery site

- Amazon.com