Carriage Lock Info

On this page

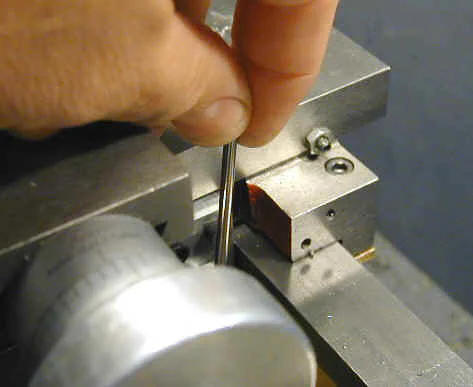

Here’s a great project that will make a big improvement to your minilathe: a cam-lever operated carriage lock. This unique design firmly clamps the saddle to the ways by applying downward force directly under the center of the saddle.

A quick flip of the lever with fingertip pressure instantly locks or unlocks the carriage.

Over 30 pages of detailed instructions loaded with shop tips, dimensioned drawings and over 50 full-color close-up photographs will guide you step-by-step to a successful implementation.

When you’re done, you’ll have a great new accessory that will improve your productivity and precision every time you use your lathe.

Note: the instructions provided are specific to the Sieg-made 7x mini-lathes such as the Harbor Freight 7x10, Grizzly 7x12 and the new-style Homier 7x12.

The instructions can most likely be adapted to work for the older-style Homier 7x12, and other lathes but I have not tested this.

If you make no other modifications to your mini-lathe, a carriage lock is probably the biggest single improvement you can make.

Any time you make a facing or parting cut, the pressure of the cutting tool against the work will tend to push the carriage towards the tailstock.

If the carriage is not locked in place, the result of the facing cut will be a shallow convex cone shape rather than a perfectly flat face.

Any movement of the carriage during a parting cut can cause excessive chatter and may cause the tool to jam in the work, possibly breaking the tool and maybe even ruining the workpiece.

One solution to this problem is simply to lock the carriage using the half-nut lever to lock the carriage onto the stationary leadscrew.

This will help to prevent the carriage from drifting towards the tailstock, but does very little to prevent any vertical movement of the saddle if the saddle plates are not real tight.

To the best of my knowledge Varmint Al posted the first carriage lock mod for the 7x lathes. Within days of receiving my first 7x lathe, I made this mod and improved it by adding a tommy bar so that I did not have to search for the proper size hex wrench.

Back then, I had not yet learned how to do threading on the lathe, so I simply adapted an off-the-shelf bolt. The beauty of this mod, is that it takes very little time to do, and is pretty effective.

The disadvantage to it, as many have pointed out, is that it tends to lift the saddle up from the ways rather than clamping it down tighter to them.

If the saddle plates are properly adjusted, this is not much of an issue, but is still a valid point.

In response to this concern, a number of owners have devised carriage locks that clamp the saddle to the ways. Vikki Ford’s version is a good example.

My design takes this concept even further, by spreading the locking force evenly across the saddle rather than clamping at a single point. That, plus the cam lock lever, make it a very nice to use.

Skill Level: Intermediate/Advanced

Topic Length: approximately 34 pages when printed

Materials Needed

- 1/8" drill rod, 3" length

- 5/16" drill rod, 4" length

- 1/2" dia. brass round, 2" length

- 3/4" dia. drill rod, 2" length (aluminum or brass could substitute)

- 3/4" dia.

aluminum round, 6" length (drill rod could substitute)

- 1/4" aluminum plate, about 6 square inches

- aluminum block approximately 1 x 1 x 1 1/2

- 6-32 x 1/2" socket head cap screws (4)

- 4-40 x 3/8" socket head cap screw (1)

- 4-40 x 1/8 set screw (1)

- 1/8" dia.

Teflon rod; 2" length

Note: as always, it is a good idea to have extra materials on hand in case you make a mistake during any of the operations.

Tools Needed

- Mini-mill or equivalent

- Four-jaw chuck

- Dial Indictor

- Bandsaw (optional, but preferred) or hacksaw

- Disk/Belt sander (optional)

- Surface plate (optional)

- Height gage (optional) or surface gage

- Over/Under chucking reamer set; 1/8 to 1/2" by 16ths, or individual reamers as follows:

- 1/8 - .001 (.124)

- 5/16 + .001 (.3135)

- The usual drills, taps and standard shop tools.

Standard shop tools such as dial calipers, drills, taps, etc.