Homepage

Your source for information on the 7x10, 7x12, 7x14 and 7x16 mini-lathes.

Mini-lathe.com is an extensive information resource for the 7×10, 7×12, 7×14 and 7×16 mini lathes. This site is intended primarily to help new and prospective owners understand the capabilities, limitations and frustrations of these tools and how to modify and fine-tune them to get results you might expect only from a much more expensive lathe.

During the years since I began this site in 2000, I have also used and written reviews on some larger lathes and related equipment.

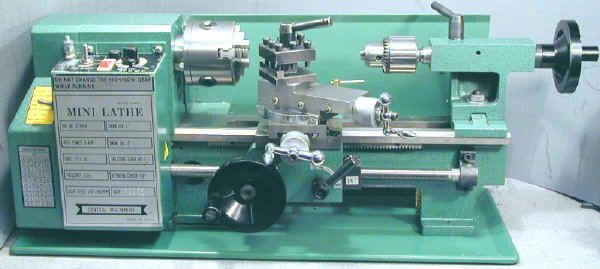

1999 Central Machinery 7×10 mini lathe from Harbor Freight

1999 Central Machinery 7×10 mini lathe from Harbor Freight

Sold by a number of vendors for around $500 to $900, these versatile small lathes are a good choice for model makers, experimenters, inventors and just about anyone else who is interested in metalworking or has a need to fabricate small precision parts.

These lathes are miniature versions of industrial metal-working lathes and are quite different in design and use than wood-working lathes, but they can certainly be used for shaping wood, plastics and other materials, especially if very accurate dimensions are required. If you follow the links on the navigation bars above, you will find a great deal of information about these lathes and related topics.

The designations 7×10, 7×12, 7×14 and 7×16 refer to the maximum diameter and length (in inches) of a workpiece that the lathe can work on. All four lathes can rotate a 7″ diameter workpiece up to approximately 10, 12, 14 or 16 inches long, depending on the model.

In practice though, the workpieces usually are limited to 4″ diameter or less, due to various factors described throughout this site. It is possible to machine the ends of shafts longer than the lathe if the diameter is 3/4″ or less so that it will pass through the hollow lathe spindle.

Fundamentally, a lathe is used to make components such as shafts and bushings that are basically cylindrical in shape. While that may not seem like much, the fact is that nearly all mechanical and engineering devices rely on components made on a lathe.

So if you have interests such as RC cars, planes, boats or helicopters; robotics, atronomy, microscopy, horology; are an inventor or just like to repair cars, motorcycles, household fixtures and appliances, a lathe is a great tool to have. Lathes are also used by artisans to make beads, bangles and other items for jewelry.

If you have never run a metal lathe before, or it’s been many years since you last did in your high school shop class (back when high schools still had shop class!), you can find some helpful information on the Introduction, Getting Started, Tool Grinding and Adjustments pages.

The mini-lathe has a lot of potential but has some shortcomings that you should be aware of before you decide to buy one – see the Reviews for more information on specific models. Fortunately, there is now a great deal of information available about this lathe on the internet, so you are not on your own if you encounter a problem.

I’m happy to report that the quality of these lathes has steadily been improving. Back in 2000, when I started this site, the variable speed motor controllers had a high failure rate, but the newer ones are much more reliable. Similarly, the overall quality of workmanship is better on the newer lathes.

While you still may find some minor defects, nearly all of them are now ready to use out of the box after a brief cleanup and performing some minor setup and adjustments. See the Getting Started page for details. The onerous cleaning off the packing grease is no longer necessary as the lathes being shipped since around 2010 have just a light coating of rust-inhibiting grease.

If you are considering purchasing one, the product review pages will give you some detailed comparisons among various models. You may also find my thoughts on Which Lathe to Buy helpful in making your decision.

The great majority of mini-lathes sold in the U.S. and worldwide are made by Sieg in Shanghai, China. They are re-branded by several vendors, painted in a variety of colors and sold with various combinations of accessories and with four bed lengths: 8″, 12″, 14″ and 16″, but all are basically the same lathe (Well, ok, the Micro-Mark version is kinda unique…).

A very similar lathe, made by Real Bull in China, makes up the rest of the market.

While this site focuses mainly on the Chinese mini-lathes, be sure to check out the slightly smaller, but very capable and high-quality lathes made in the U.S. by Taig and Sherline; they’re very popular among precision model makers.

When I began this site, I was using the 7×10 version of the mini-lathe, shown above. While the 7×10’s are still available, the 7×12 is more common nowdays, and for good reason: it’s actually 4″ longer than the 7×10 (a result of overly optimistic marketing of the 7×10; which is really only 7×8).

Since the mini-lathe is now available in four lengths (8″, 12″, 14″ and 16″), you will find references to all four models throughout this site. Most of the features and capabilities are very similar, other than the maximum working length. You may also see references to “7x” lathes where I am referring to all four sizes generically.

Specific features of these lathes are continually being improved by the manufacturer. Therefore, some of the older information on this site may no longer be relevant. For example, the lathes made before 2000 had a somewhat crude motor speed control with a minimum speed of about 100 RPM.

The motor speed controls have been continually improved since then and the newer ones are much more sophisticated and reliable than the very early ones.

Beginning around 2007, Sieg introduced the “S” series of machines which have brushless DC motors. These new motors have much more torque than the prior motors, so that the internal HI-LO range gears are no longer needed. The result is a quieter, more powerful and more reliable machine. The newer lathes also include some improved safety features over the older ones.